All-In-One Full Glass Bottle Inspection Machine

The development of modern technology has made the production process more efficient, precise and controllable. The full bottle inspection machine Promita-G One, as an all-in-one integrated inspection system, can provide companies with online inspection of full bottles after filling and rejection of defective products in the beer production line. It is capable of accurate and reliable inspection of product quality such as fill level, cap position, and code to ensure that the quality of the produced product meets the standard. This advanced technology can not only improve the production efficiency of enterprises, but also provide consumers with safer and better quality products.

|

Scope of application:

|

Installation Location:

|

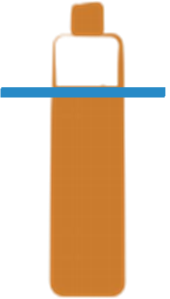

Fill level inspection

Fill level inspection

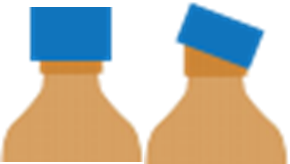

Cap inspection

Cap inspection

Code inspection

Code inspection

Filling Management System

Filling Management System

Cover top logo inspection

Cover top logo inspection

|

|

|

|

Low level |

Broken cap |

No cap |

|

|

|

|

Code missing |

|

|

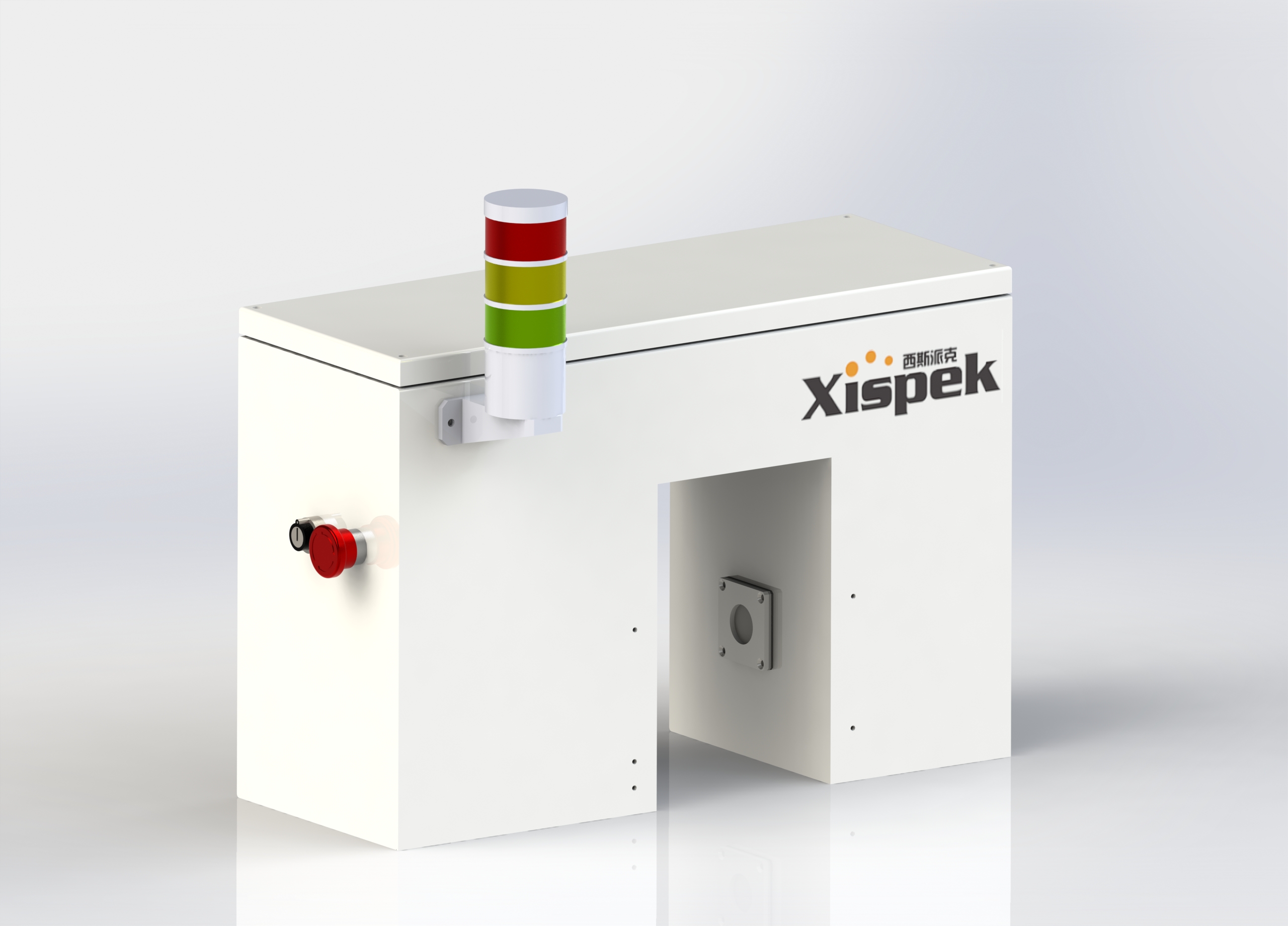

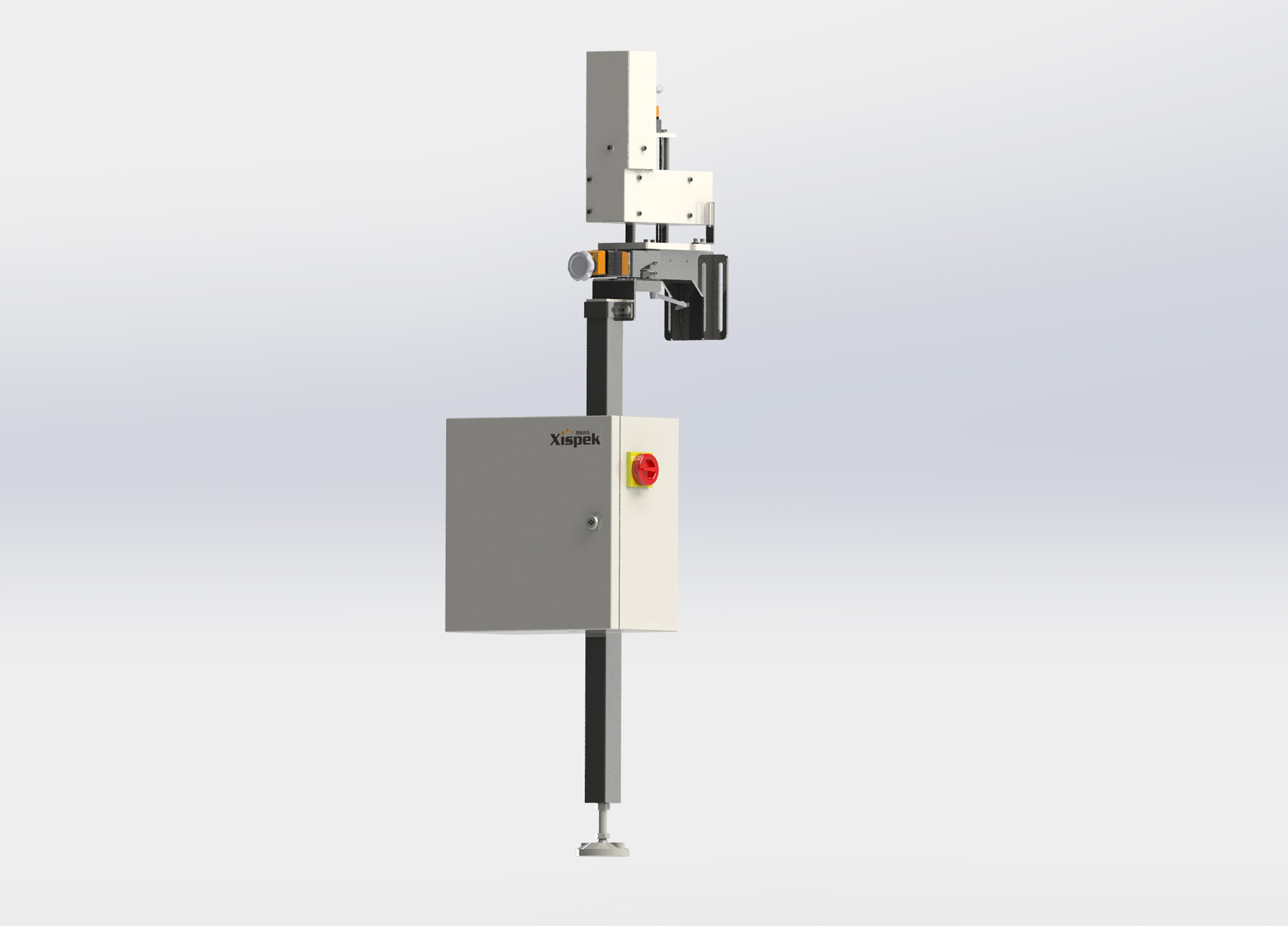

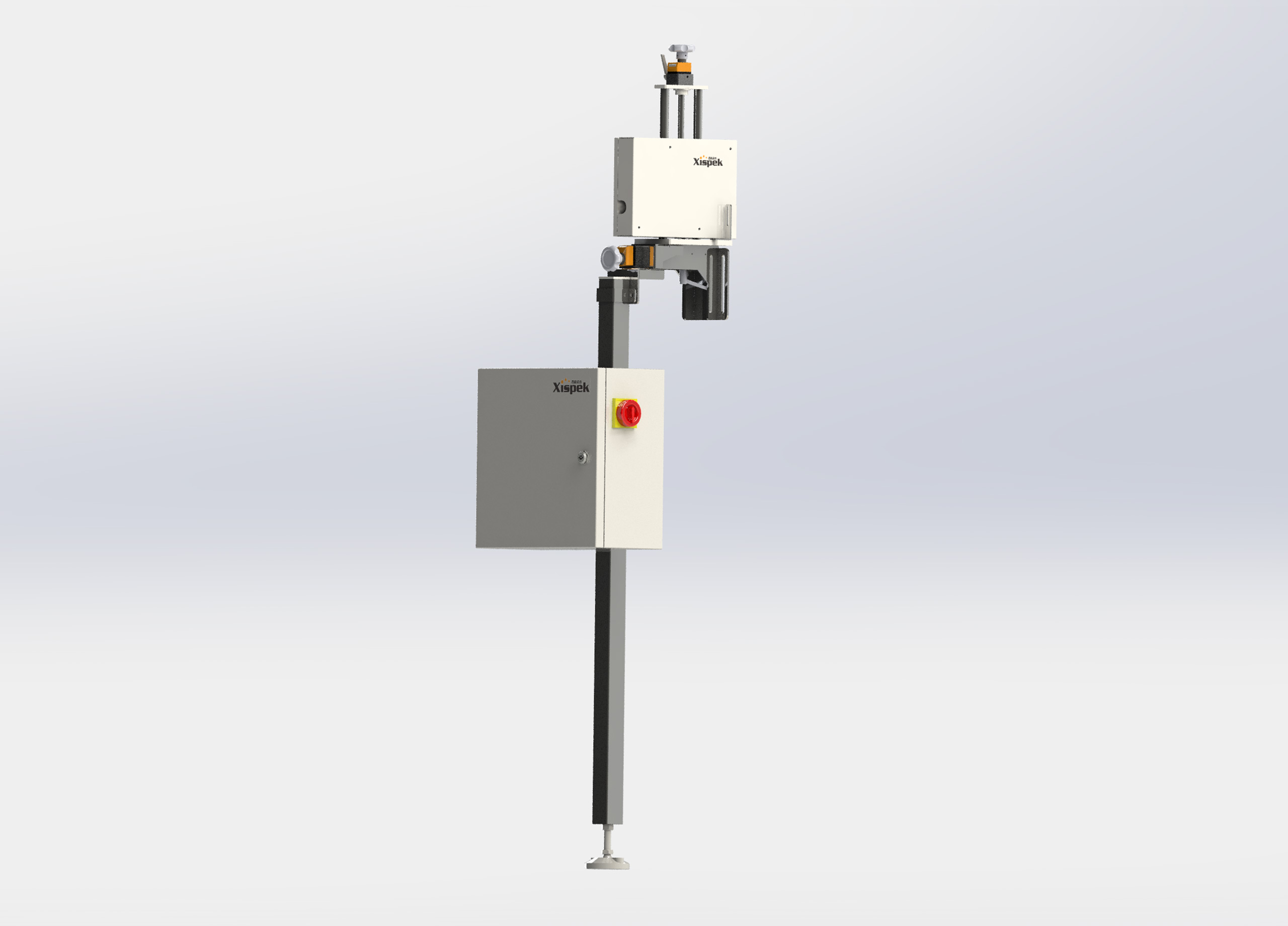

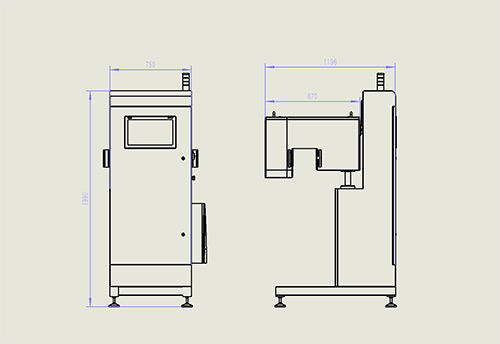

The Xispek Promita-G One is an all-in-one full bottle inspection system designed for the needs of glass filling lines. It features fully motorized height adjustment and easy one-button changeover. It provides effective inspection of the filling level, slant cap and filling tube inside the bottle. The combination of images and sensors ensures that each container is inspected accurately, and the Promita-G One is available with different integrated control centers depending on the actual line speed, up to 72,000 bottles/hour.

Adopts XispVision® universal inspection software platform

Adopts XispVision® universal inspection software platform

High inspection efficiency and accuracy

High inspection efficiency and accuracy

Compact design for easy integration

Compact design for easy integration

Inspection module with IP65 protection level

Inspection module with IP65 protection level

Motorized lifting system, one button to changeover

Motorized lifting system, one button to changeover

Use one industrial camera

Use one industrial camera

Maintenance-free and long-life infrared LED light source with stronger penetration and higher contrast imaging

Maintenance-free and long-life infrared LED light source with stronger penetration and higher contrast imaging

Simultaneously detect high and low fill level

Simultaneously detect high and low fill level

X-ray optional

X-ray optional

Use industrial camera

Use industrial camera

Maintenance-free and long-life white LED light source

Maintenance-free and long-life white LED light source

Backlit way, high contrast imaging

Backlit way, high contrast imaging

Simultaneously detect: no cap, no tamer ring, high cap, slant cap

Simultaneously detect: no cap, no tamer ring, high cap, slant cap

Use two color industrial camera

Use two color industrial camera

Maintenance-free and long-life LED surface light source

Maintenance-free and long-life LED surface light source

Compact design through specular reflection

Compact design through specular reflection

Four sides of the cap are photographed to realize a 360 panoramic image

Four sides of the cap are photographed to realize a 360 panoramic image

Intelligent recognition algorithm, able to realize 0.7mm broken tamper ring

Intelligent recognition algorithm, able to realize 0.7mm broken tamper ring

Using the fill level inspection or high/slant cap inspection data, to inspect the code

Using the fill level inspection or high/slant cap inspection data, to inspect the code

Temperature sensors optional

Temperature sensors optional

TrackML® Patented Tracking Technology

TrackML® Patented Tracking Technology

Object-oriented ID tracking

Object-oriented ID tracking

Stabilized real-time tracking

Stabilized real-time tracking

Multi-module tracking and delivery

Multi-module tracking and delivery

Individual statistical summary for each filling nozzle(capping nozzle)

Individual statistical summary for each filling nozzle(capping nozzle)

Analyzing equipment problem diagnosis

Analyzing equipment problem diagnosis

Sampling function

Sampling function

Subdivision of statistics by machine position

Subdivision of statistics by machine position

Graphic report function

Graphic report function

Use one color industrial camera

Use one color industrial camera

Maintenance-free, long-life ring LED light source

Maintenance-free, long-life ring LED light source

Inspection wrong cap by color and pattern

Inspection wrong cap by color and pattern