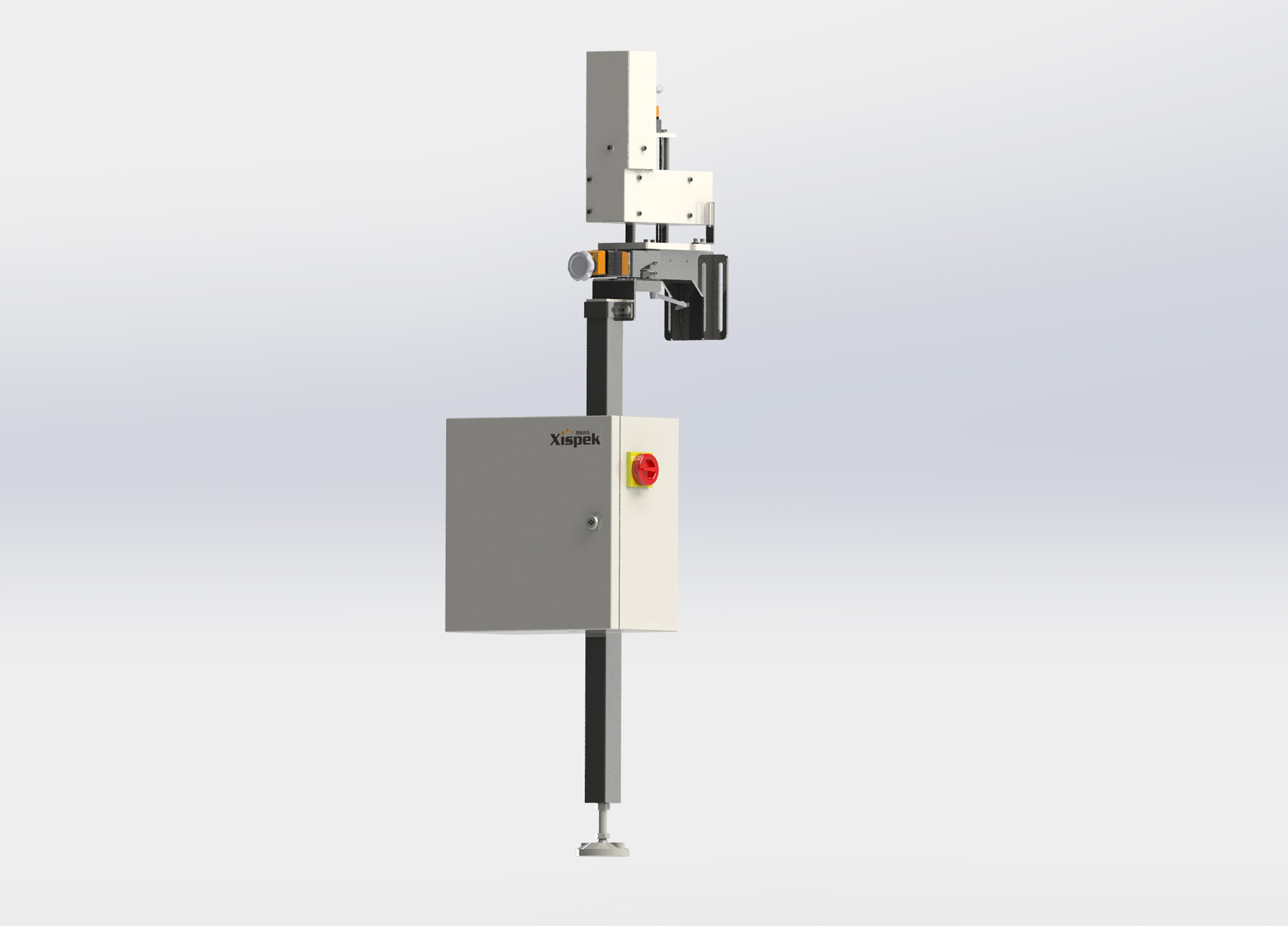

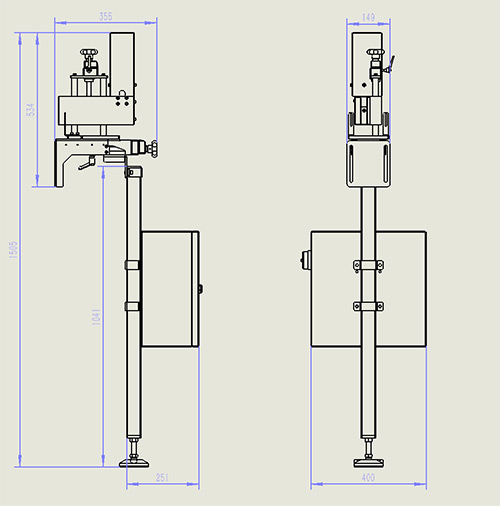

The Servo-Motor Pusher PU-SM-90 is a device that uses a servo motor as a drive source for rejecting defective products on automated production lines. It combines servo control technology with a mechanical actuator for more accurate and reliable reject operations.

|

Scope of application:

|

Installation position:

|

Defective products rejection

Defective products rejection

Servo-Motor PusherPU-SM-90 is designed to remove defective products from the production line by tracking and controlling the products to be rejected to a specified position after inspection by the inspection system and giving a rejection signal. Upon receiving the rejection signal, the servo-motor will execute it in a preset curve and drive the mechanical actuator to complete the rejection action.

Compared with pneumatic rejector, servo-electric rejector PU-SM-90 does not need external air supply, which is more energy-saving and environmentally friendly, and it is more stable as there will not be a decrease of rejecting strength caused by insufficient air supply during continuous rejecting. It is more flexible to use, different rotation curves can be edited, multi-channel input, to realize different speed and strength of the rejecting effect, the highest speed can be achieved 90,000bph.

Adpots XispVision® universal inspection software platform

Adpots XispVision® universal inspection software platform

Precise rejection with controlled intensity

Precise rejection with controlled intensity

Compact design for easy integration

Compact design for easy integration

No external gas source, energy saving and environment friendly

No external gas source, energy saving and environment friendly

Lower cost, durable and easy to maintain

Lower cost, durable and easy to maintain