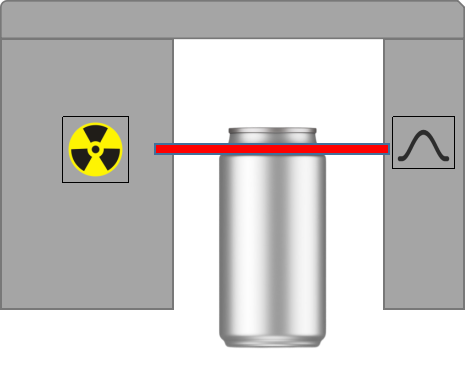

Fill level inspection Module FLI-X uses X-rays to detect high and low fill levels in containers after filling, with a wide range of transparent and opaque materials such as PET, glass and cans.

Scope of application: PET production line PET production line Can production line Can production line Glass bottle production line Glass bottle production line Opaque package production line Opaque package production line |

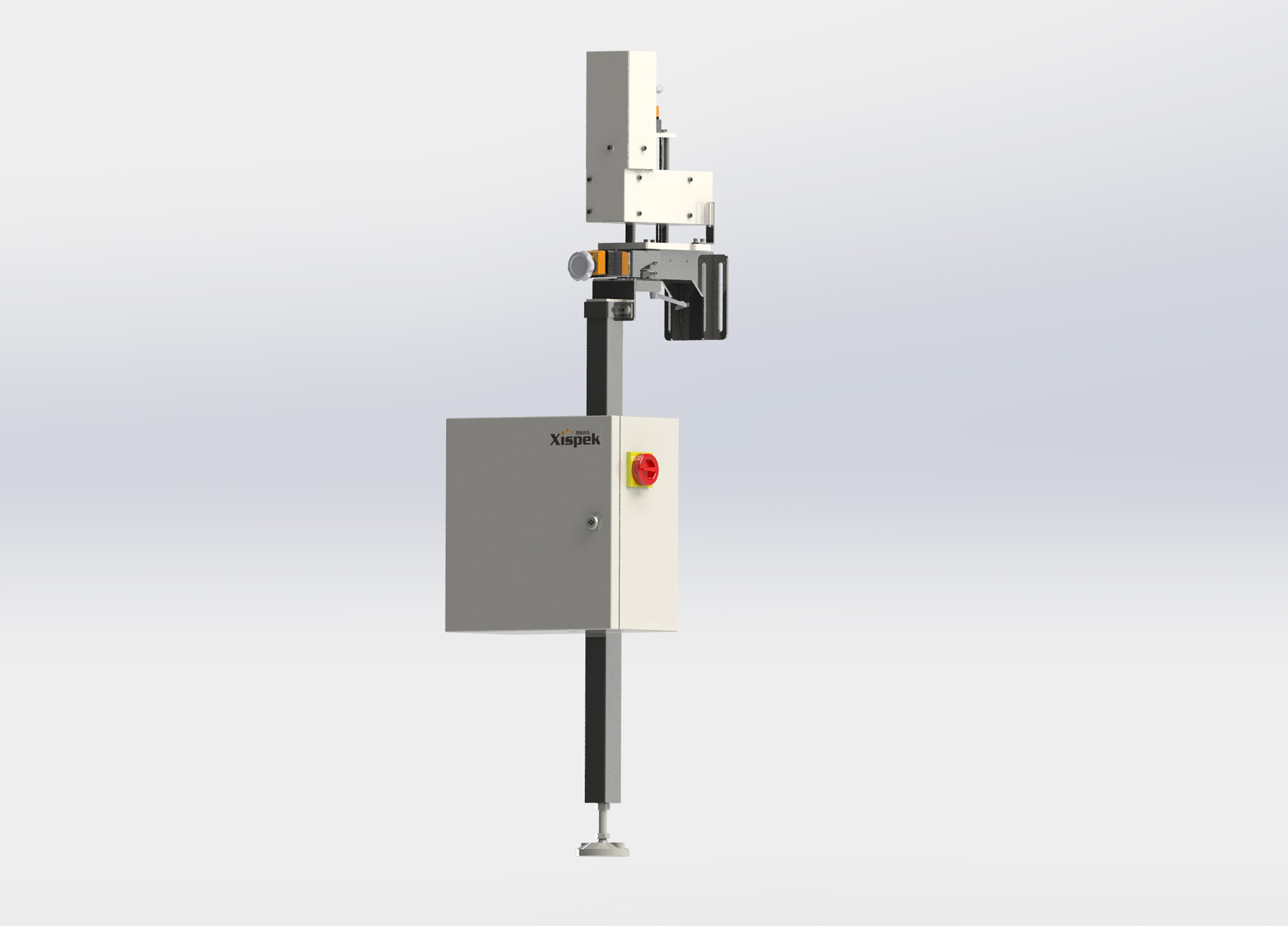

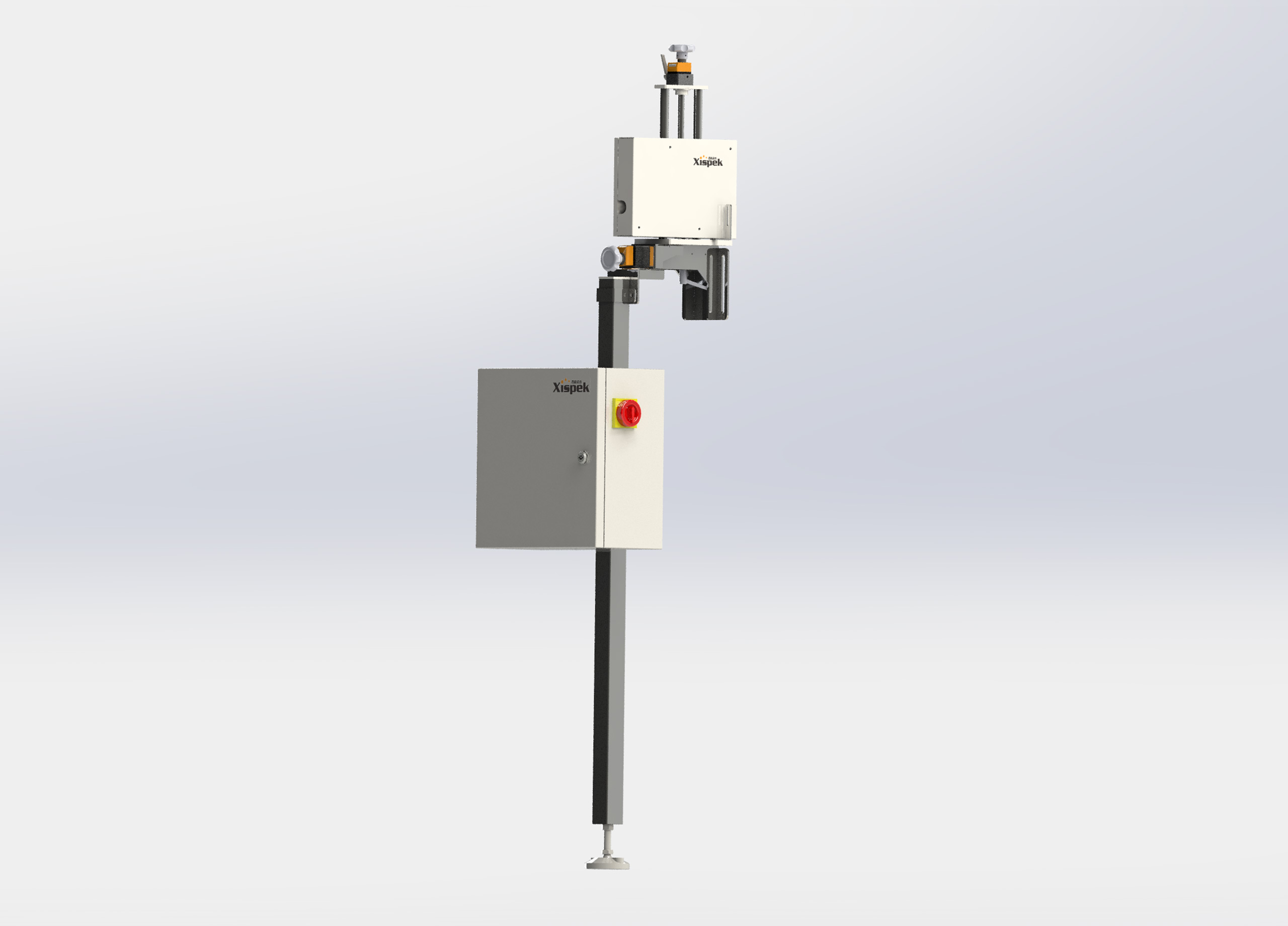

Installation position:

|

High Level

High Level

Low level

Low level

|

|

|

|

Normal level |

High level |

Low level |

Fill level inspection Module FLI-X uses ionization to emit X-rays, a non-traditional radioactive source that does not cause radioactive contamination to personnel or the environment. The inspection module can be attached directly to the conveyor, regardless of the material of the container, when the X-ray photons through the empty bottle or fill level will be blocked, the receiver will receive the X-ray value will be changed, XispVision® Universal Inspection Software Platform according to the value of the change in the judgment of the processing, to the level of the product failed to be rejected.

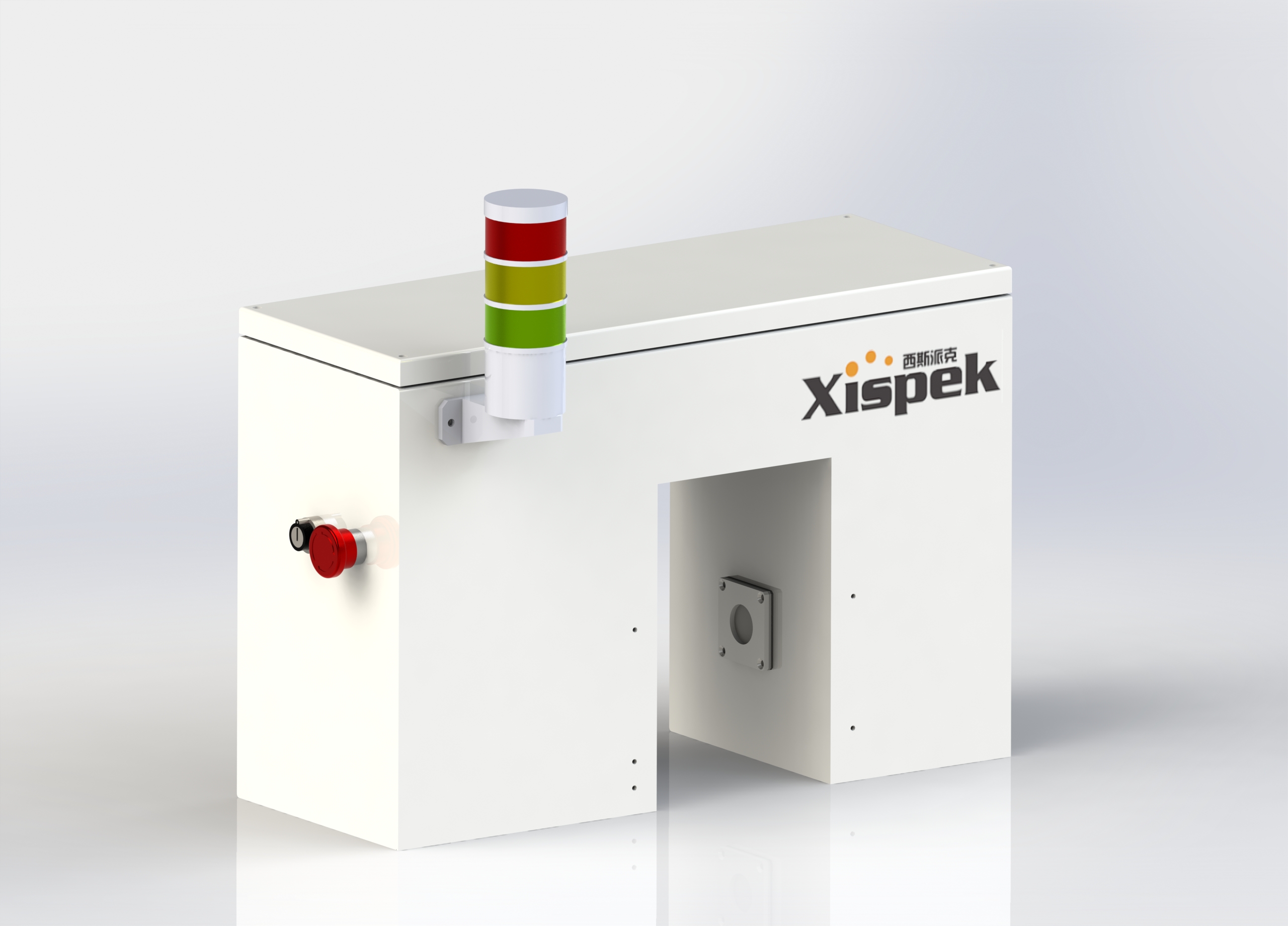

Fill level inspection Module FLI-X is an important part of the overall full bottle inspection after filling. Customers can combine other inspection modules (cap inspection module, 360-degree tamper ring inspection module, cover top logo inspection module, code inspection module IRT, etc.) according to their actual needs, as well as optional filling management system (FMS) functions, to form a complete full bottle inspection system.

Utilizes the XispVision® universal inspection software platform

Utilizes the XispVision® universal inspection software platform

Extremely high inspection efficiency and accuracy

Extremely high inspection efficiency and accuracy

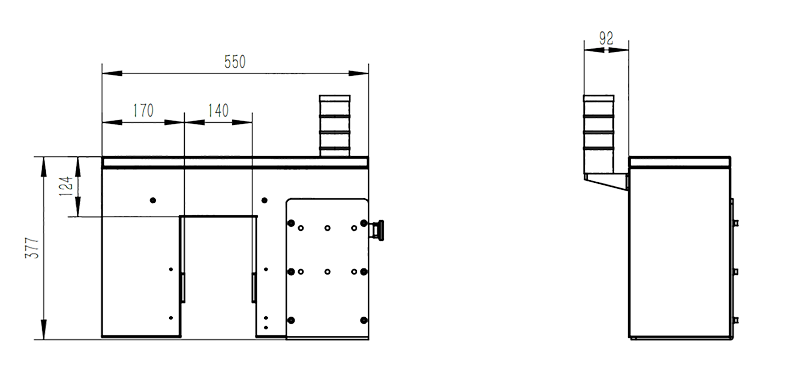

Compact design for easy integration

Compact design for easy integration

IP65 rated inspection module for harsh environments

IP65 rated inspection module for harsh environments

Customized hardware configurations are available upon request

Customized hardware configurations are available upon request