Label inspection system Exacta uses advanced visual recognition technology to inspect labels in a 360-degree view, capturing label defects including label position, joint label and label integrity.

|

Scope of application:

|

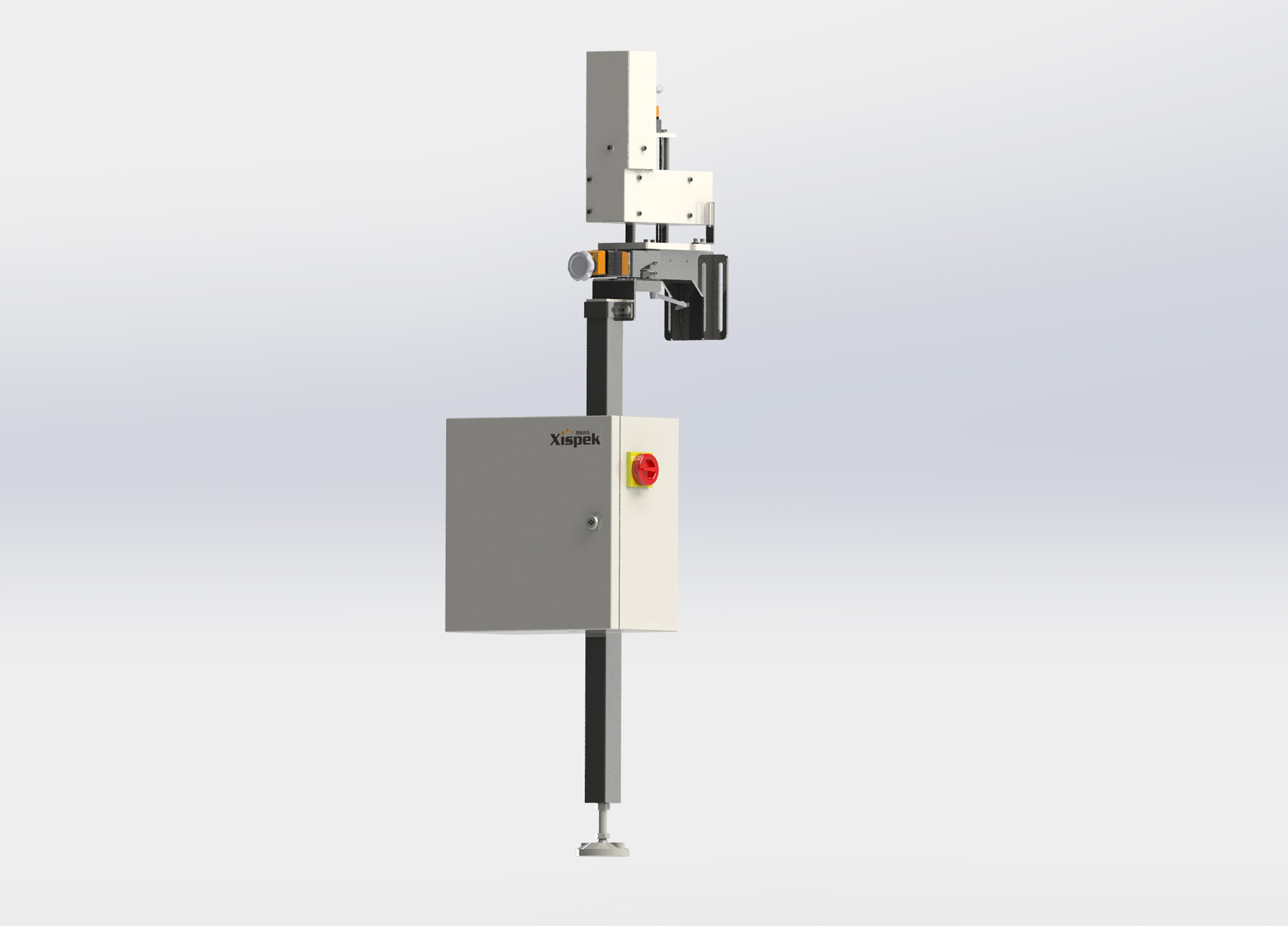

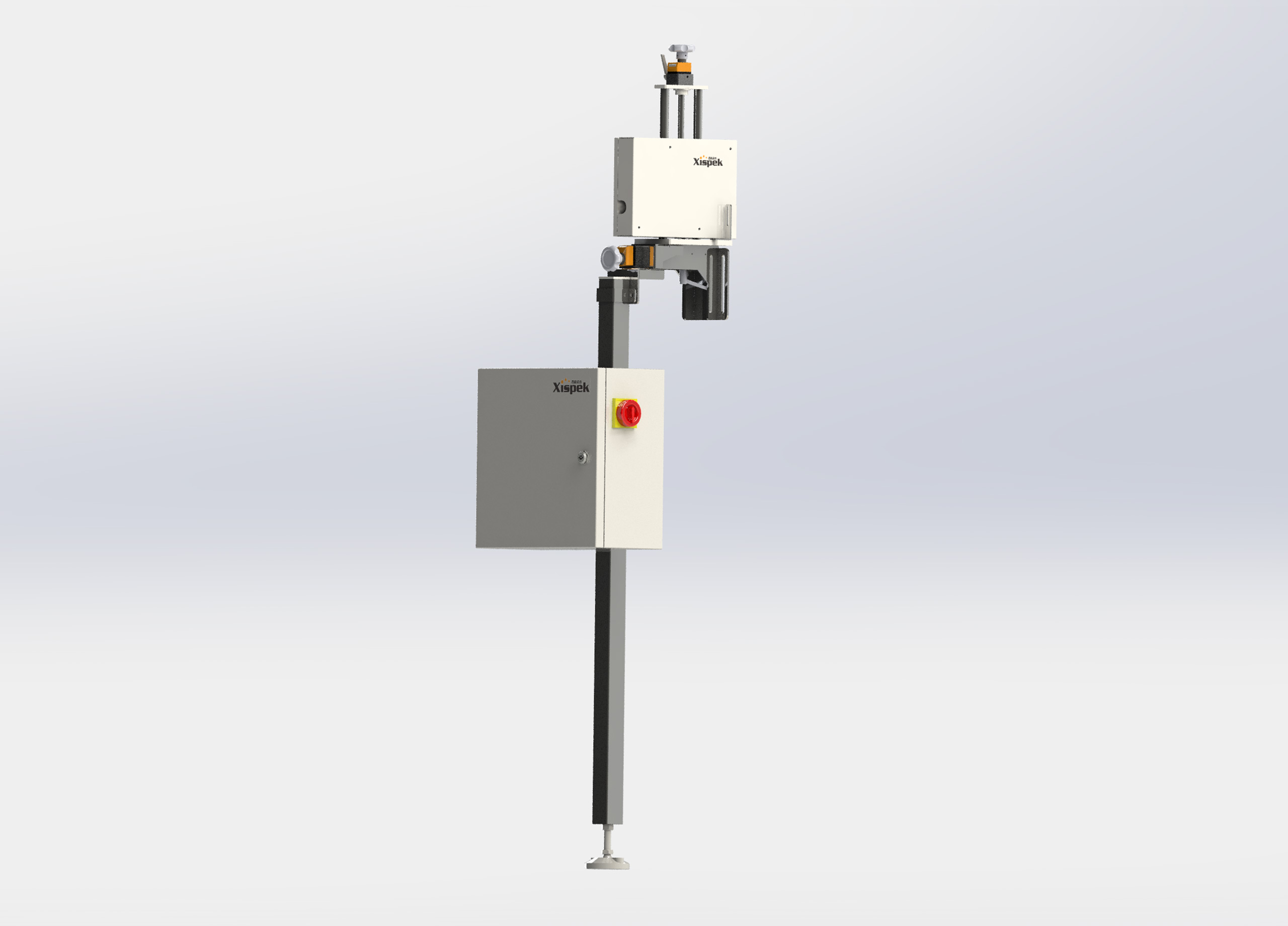

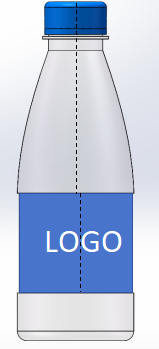

Installation position:

|

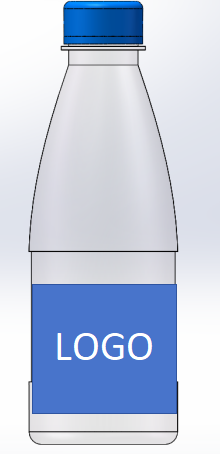

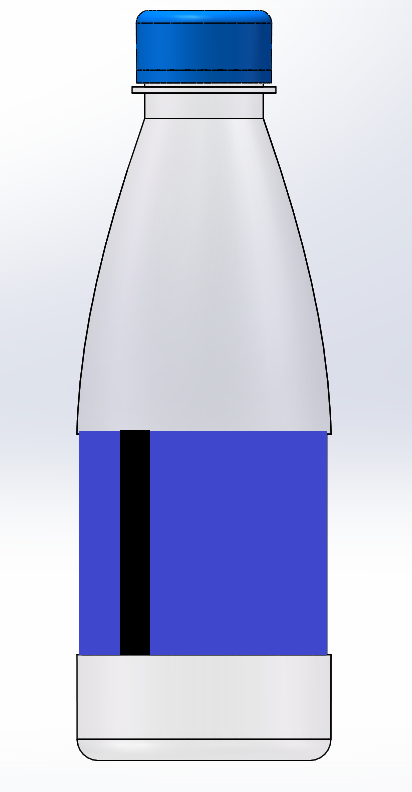

No label/wrong label

No label/wrong label

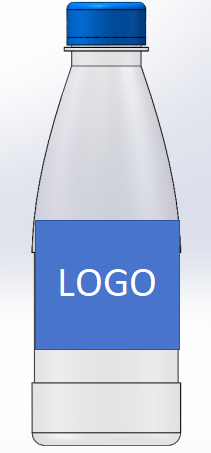

High/Low Label

High/Low Label

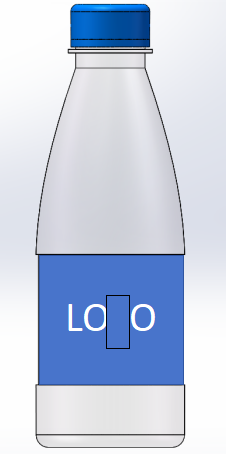

Concentricity

Concentricity

Slant label

Slant label

Joint label

Joint label

|

|

|

|

Label missing |

Low label |

High label |

|

|

|

|

Not centered |

Slant label |

Nolabel |

|

|

|

|

Joint label |

|

|

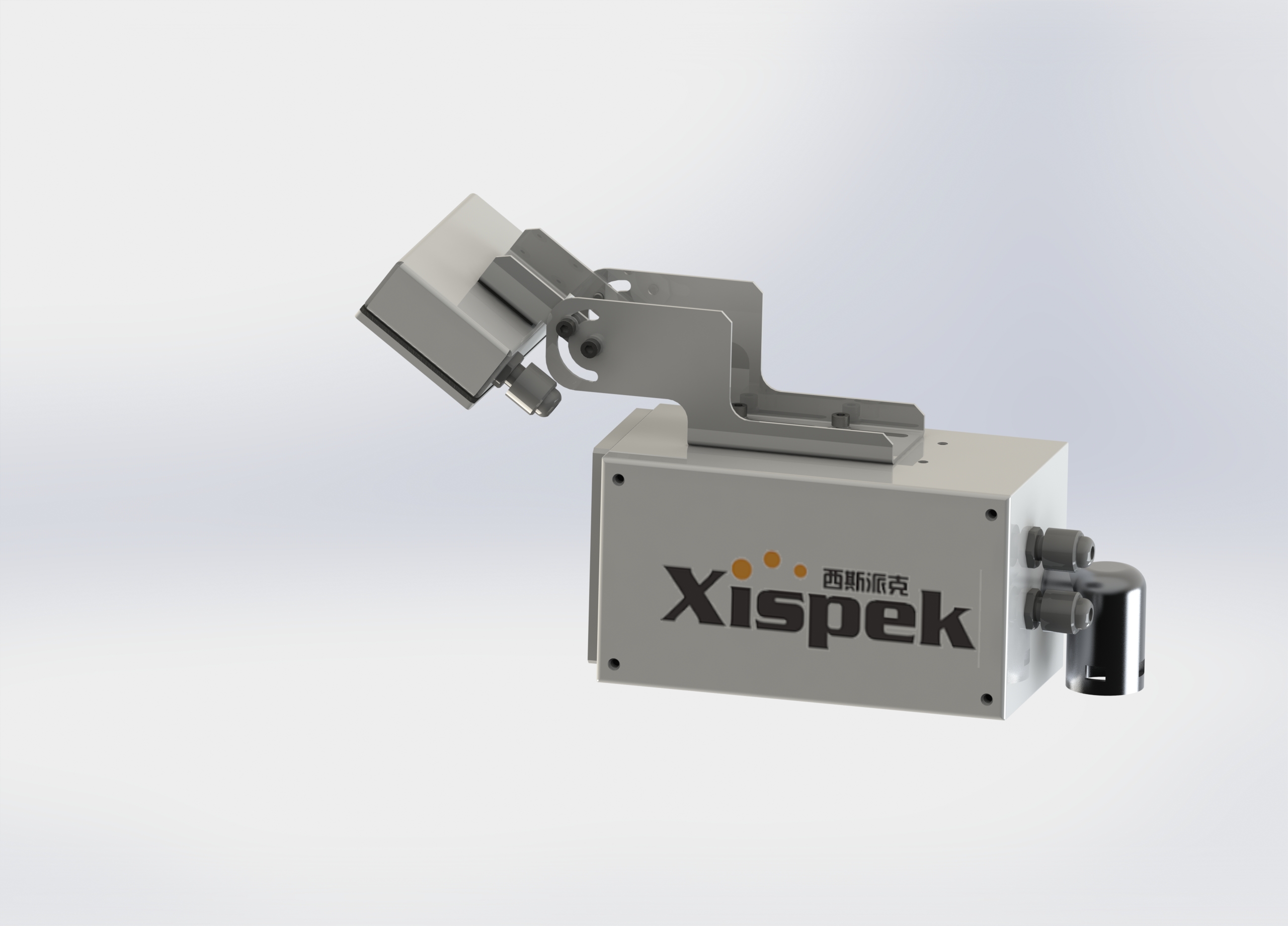

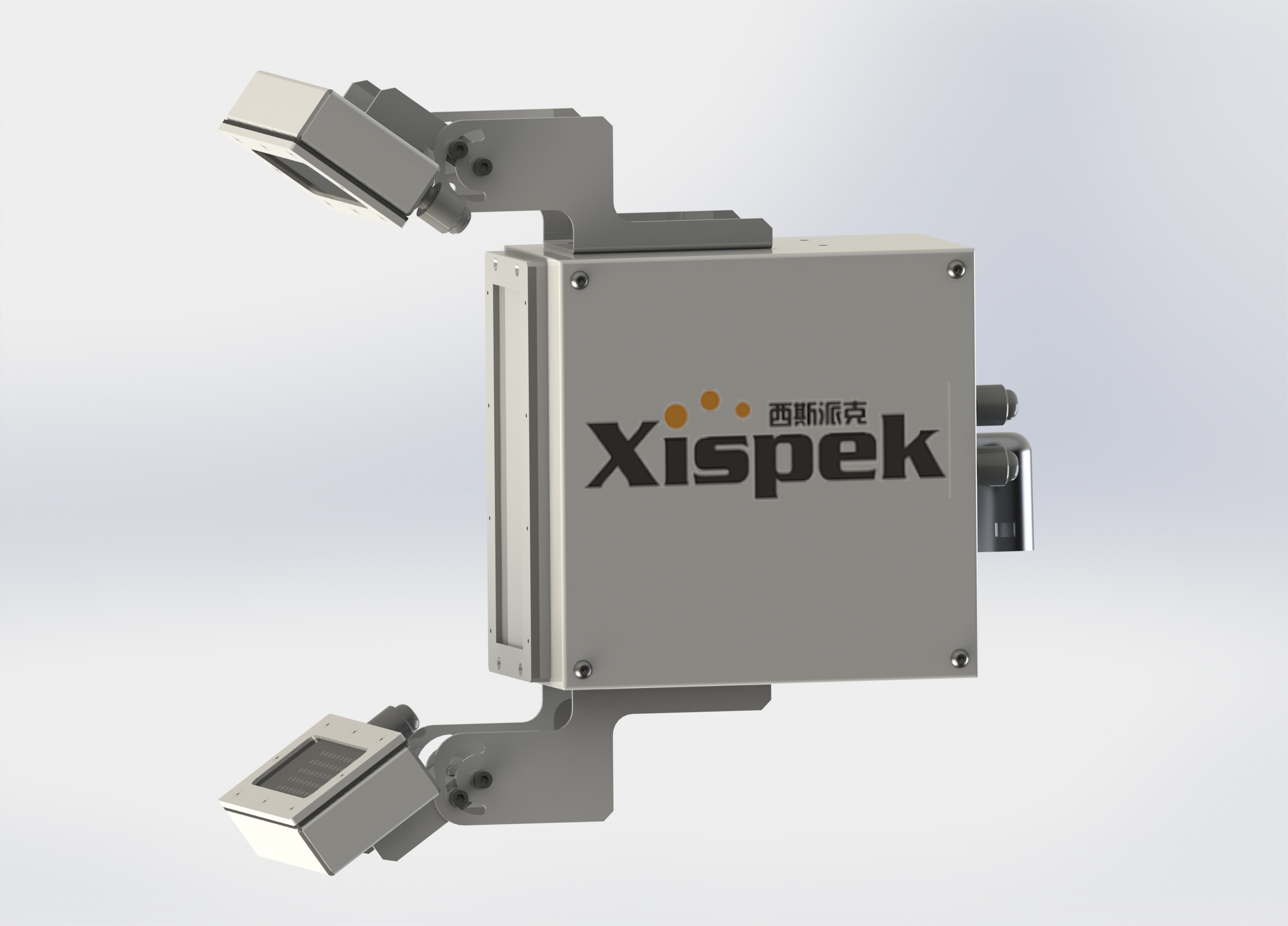

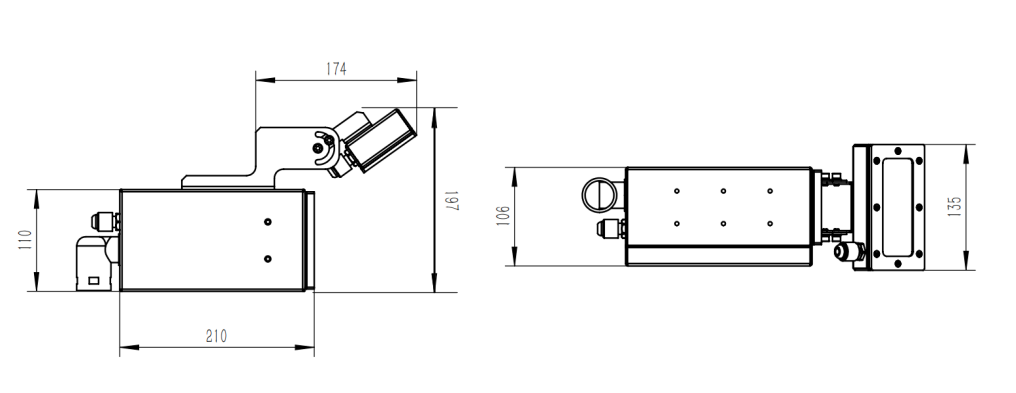

The Xispek Exacta is installed in the labeling to achieve the best inspection accuracy and stability, ensuring that your product is flawless. The compact and modular design of the Exacta allows it to be incorporated into a wide range of labeling machines, and the inspection module can be mounted in a variety of flexible locations. Different control centers are available for different line speeds, and the Exacta uses three high-speed industrial cameras to achieve label inspection speeds of up to 90,000 bottles per hour. The Xispek Exacta is ideally suited for applications such as carbonated beverages, water and beer production lines where multiple labels or multiple parts of the same label are inspected.

Typically Exacta consists of three cameras mounted inside the labeling machine for inspection of the container's front, back and neck labels. Depending on the speed of the production line different control centers can be selected. On request, it can also be integrated with the coding inspection on the labels, which can be controlled from a single control center.

Adopts XispVision® universal inspection software platform

Adopts XispVision® universal inspection software platform High inspection efficiency and accuracy

High inspection efficiency and accuracy Compact design for easy integration

Compact design for easy integration Flexible adjustment of the installation position according to the position inside the labeling machine

Flexible adjustment of the installation position according to the position inside the labeling machine Inspection module with IP65 protection level

Inspection module with IP65 protection level