Etika360 label inspection system uses advanced visual recognition technology to inspect labels in a 360-degree view, capturing defects on every angle, including label position, slant label, and label integrity.

|

Scope of Application:

|

Installation position:

|

No label/wrong label

No label/wrong label

High/Low Label

High/Low Label

Slant label

Slant label

Joint label

Joint label

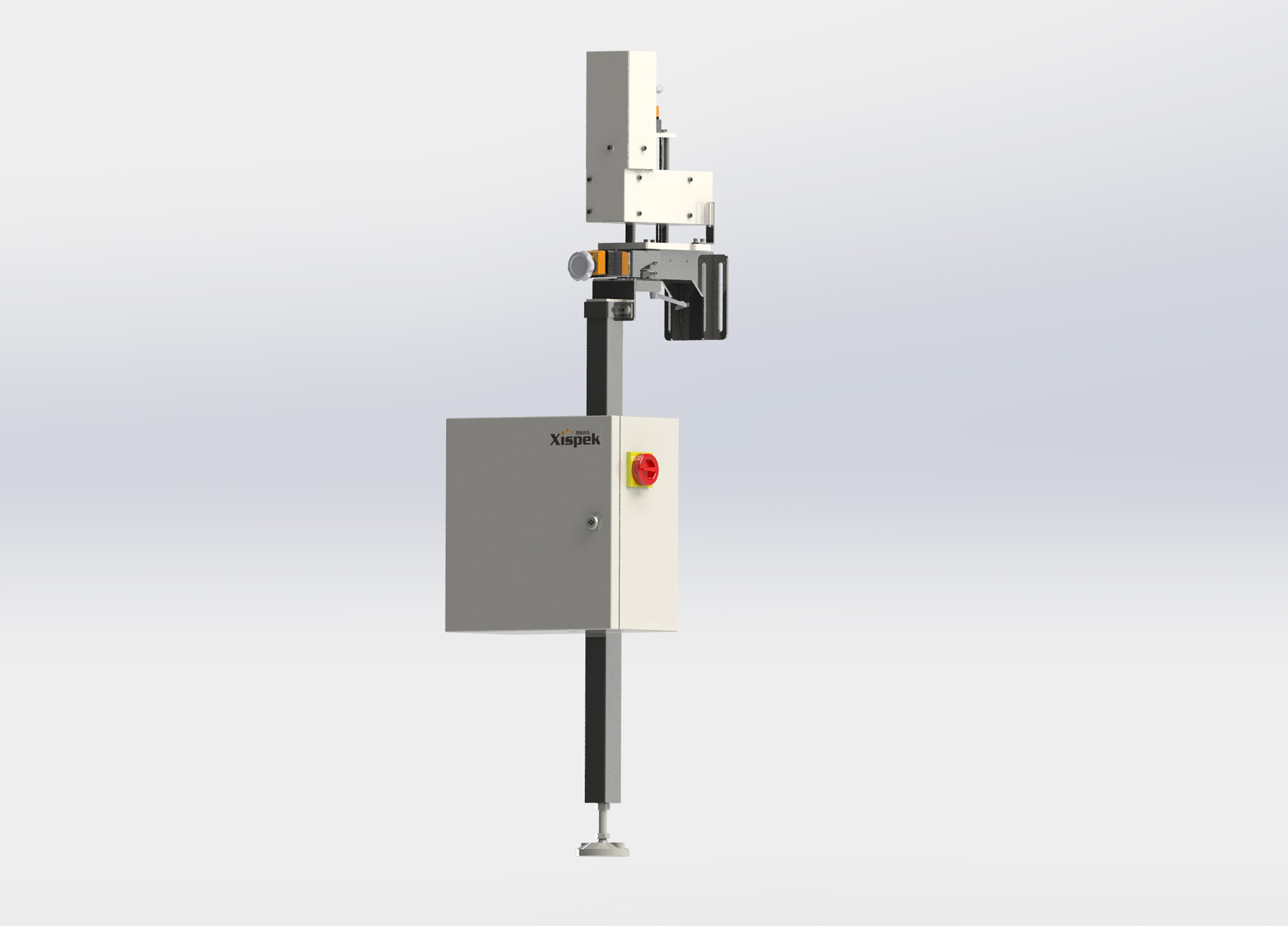

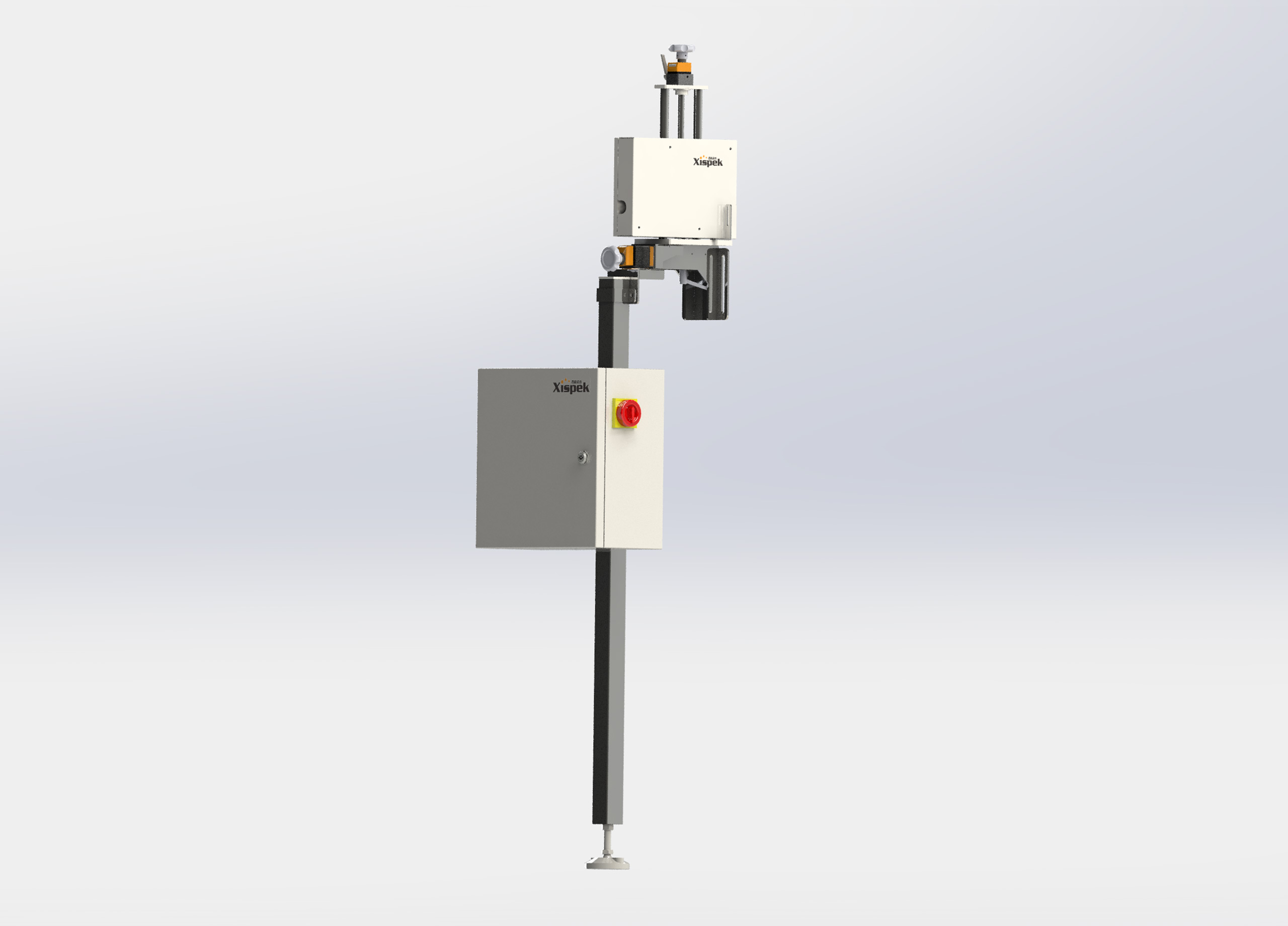

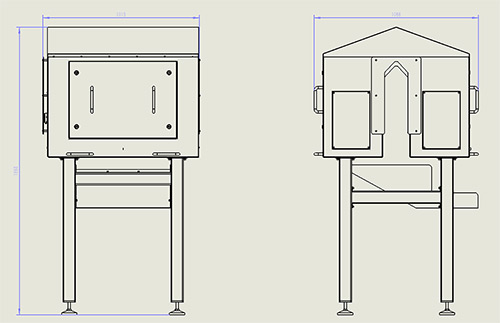

If there is no installation location within the labeling machine, or if there is no label inspection on an existing older production line, then the Xispek Etika360 is the best choice for you. Etika360 uses 4 color industrial cameras for 360 degree imaging of container labels, and through efficient image processing algorithms is able to restore the image of the entire label. The Etika 360 label inspection machine is mounted on a conveyor behind the labeling machine and is not dependent on the position or angle of the container. It can work effectively at any angle. If the line requires compatibility with square bottles in addition to round bottles, the Etika360 also offers a 6-camera option. Different control centers are available for different line speeds, and the Etika is designed to achieve label inspection speeds of up to 60,000 bottles per hour. The Xispek Etika is ideally suited for carbonated beverage and water production lines where ring labels or multiple labels are inspected.

Adopts XispVision® universal inspection software platform

Adopts XispVision® universal inspection software platform

High inspection efficiency and accuracy

High inspection efficiency and accuracy

Compact design for easy integration

Compact design for easy integration

Inspection module with IP65 protection level

Inspection module with IP65 protection level

Utilizes an in-machine thermostatic design

Utilizes an in-machine thermostatic design

Compatible with round and square bottles (Etika360-G6)

Compatible with round and square bottles (Etika360-G6)