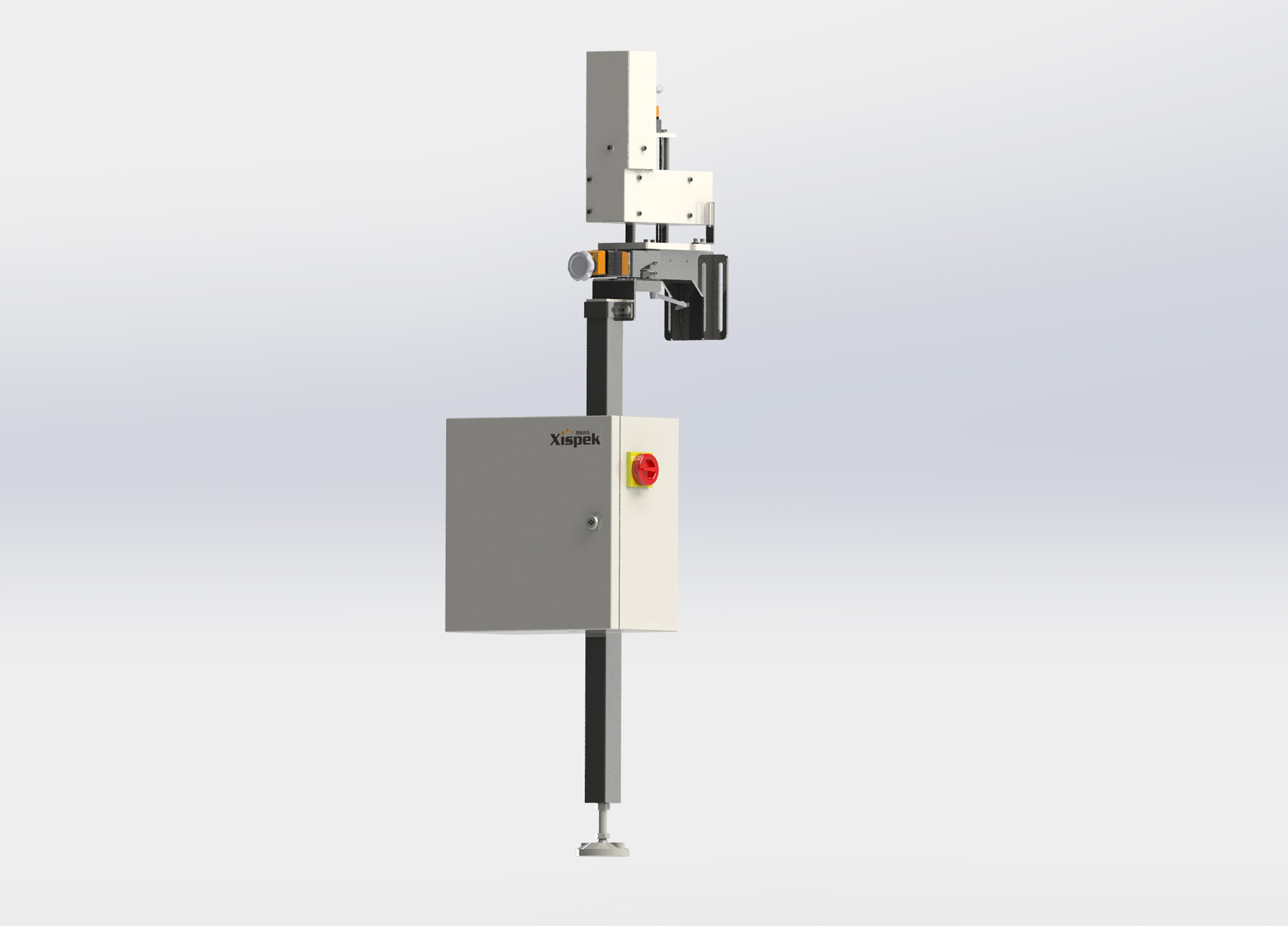

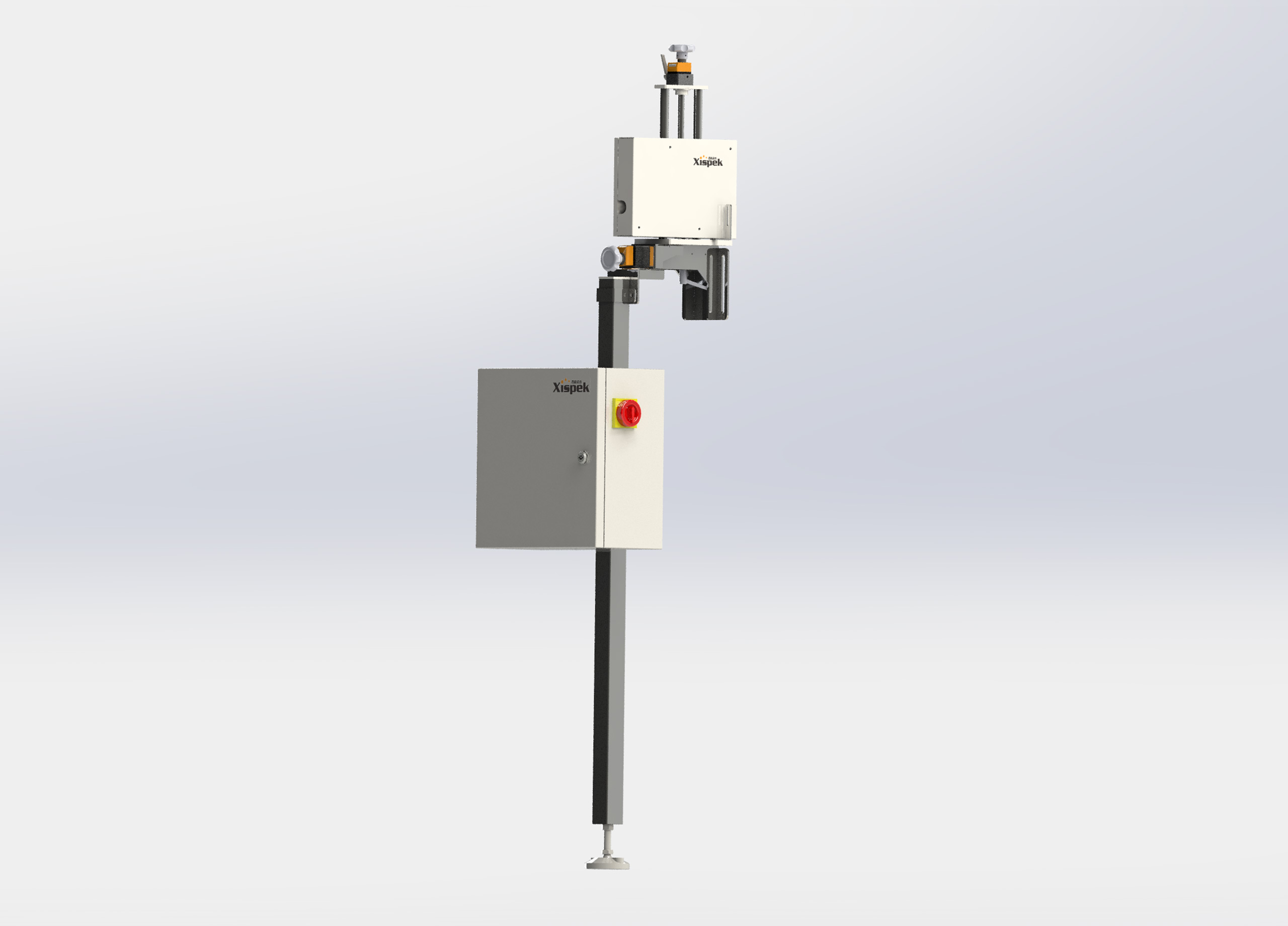

Cap inspection machine is used for inspection of cap defects before filling in PET production lines. Defective caps such as oval caps, rolled edges, incorrect sizes, dirty, wrong caps, etc., can cause filling machine downtime and subsequent product quality problems.To deal with these problems we have customized cap inspection machines to reduce downtime and improve productivity and product quality.

Scope of application: PET cap PET cap |

Installation position: Before filling machine Before filling machine |

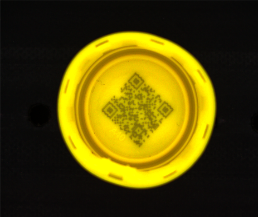

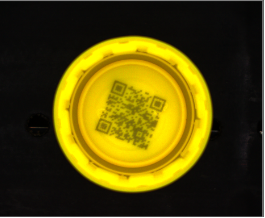

Wrong cap

Wrong cap Oval cap

Oval cap Incorrect Size

Incorrect Size Rolled edge

Rolled edge

Dirty

Dirty

Wrong cap

Oval cap

Rolled edge

Dirty

Bottle cap inspection adopts a color industrial camera to inspect the appearance of bottle caps, which can achieve an inspection speed of 72,000 BPH through efficient image processing algorithms. The cap inspection machine is mounted on the vacuum belt before the filling machine, avoiding the sliding of the caps during transportation which could affect the inspection. After inspection, the defective products are rejected by the pneumatic pusher.

Adopts XispVision® Universal Inspection Software Platform

Adopts XispVision® Universal Inspection Software Platform

High inspection efficiency and inspection accuracy

High inspection efficiency and inspection accuracy

Compact design for easy integration

Compact design for easy integration

IP65 protection level for various environment

IP65 protection level for various environment