Coding inspection is a system that is installed on the production line to inspect the codes. The system uses high-speed industrial cameras and the self-owned XispVision® universal inspection software platform to accurately and efficiently recognize codes and reject defective products.

|

Scope of application:

|

Installation position:

|

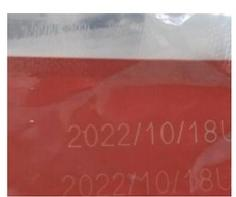

Code missing

Code missing

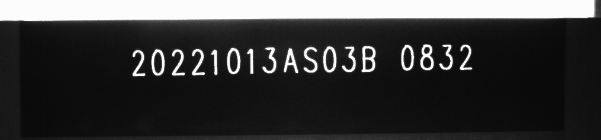

Wrong code

Wrong code

Barcode, DQ code reading and verification

Barcode, DQ code reading and verification

|

|

|

|

Aluminum foil bag code inspection |

Plastic bag code inspection |

Carton QR code identification |

|

|

|

|

Can code inspection |

|

|

|

|

|

|

| Actual shooting effect |

Code inspection is an inspection system used in production line to check the printing code. It adopts high-speed industrial camera and independent XispVision® universal inspection software platform, which can accurately and efficiently identify the presence or absence of printing code, missing characters, date and shift proofreading, and reject defective products.

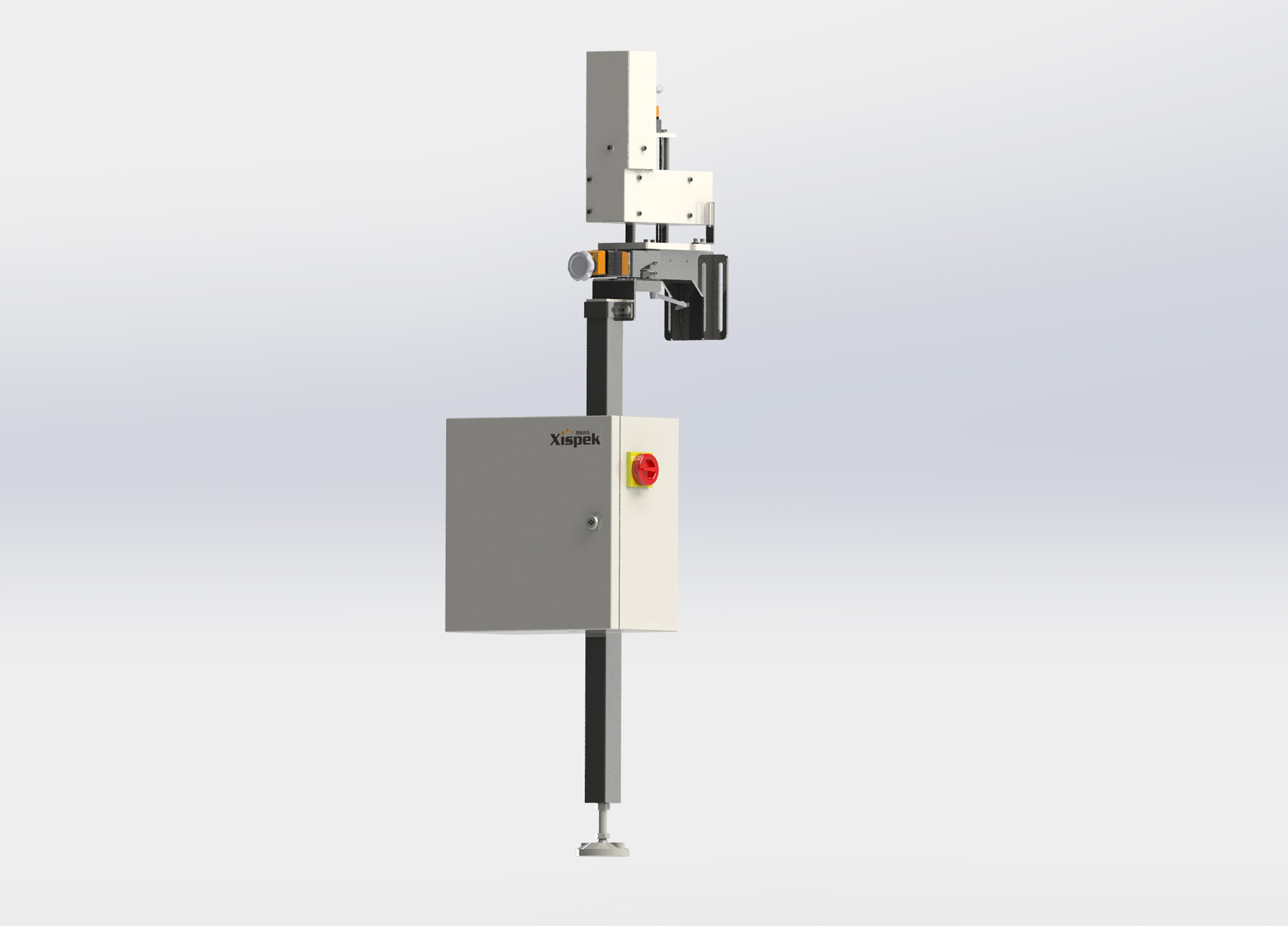

The compact, easy-to-integrate XispSmart camera offers a cost-effective solution for medium-speed production lines.

The compact, easy-to-integrate XispSmart camera offers a cost-effective solution for medium-speed production lines.

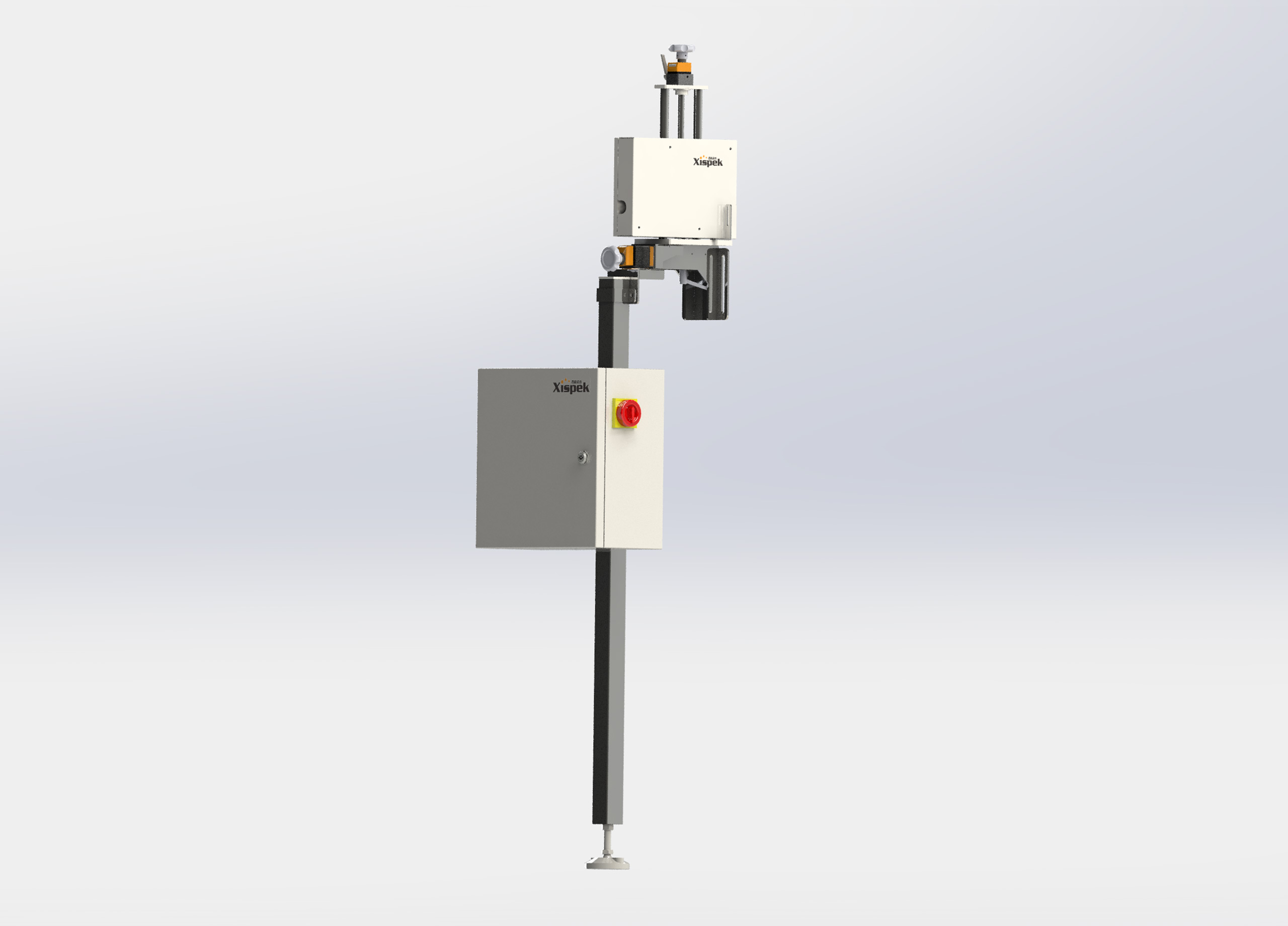

The modular architecture with the control center at the core provides the flexibility to match and expand the inspection modules and control center according to different application scenarios and the speed of the production line.

The modular architecture with the control center at the core provides the flexibility to match and expand the inspection modules and control center according to different application scenarios and the speed of the production line.

Inspection principle: the first to adopt deep learning technology, which can realize high-precision full character recognition in a variety of packaging, box type and slug scenarios.

Inspection principle: the first to adopt deep learning technology, which can realize high-precision full character recognition in a variety of packaging, box type and slug scenarios.

It can be flexibly matched and expanded according to the actual inspection needs and production line speed.

It can be flexibly matched and expanded according to the actual inspection needs and production line speed.

Adopts XispVision® Inspection Software Platform

Adopts XispVision® Inspection Software Platform

High inspection efficiency and accuracy

High inspection efficiency and accuracy

Compact design for easy integration

Compact design for easy integration

IP65 protection level, adapt to various environments

IP65 protection level, adapt to various environments

Compatible with paper, plastic, metal, and other package materials

Compatible with paper, plastic, metal, and other package materials