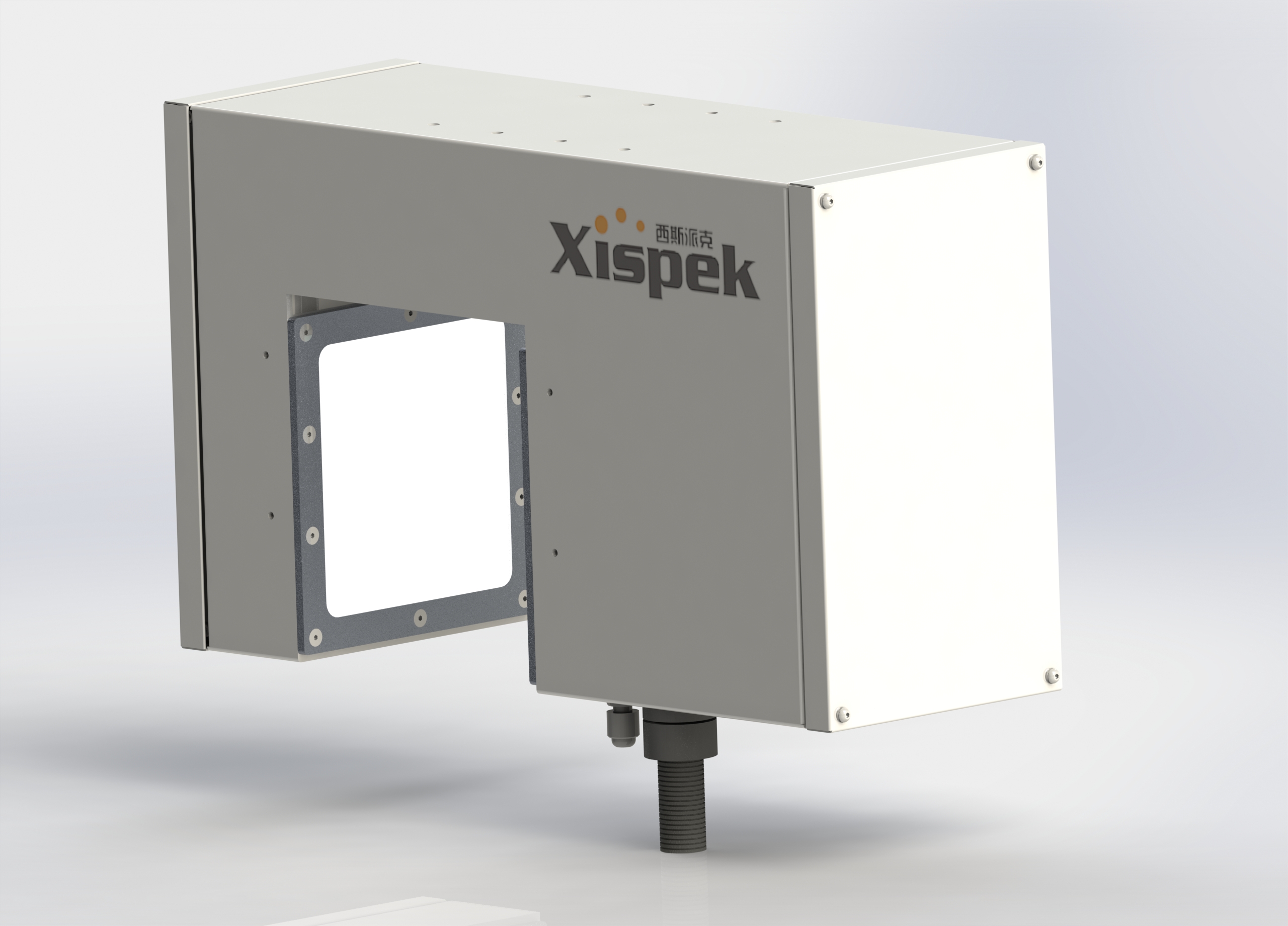

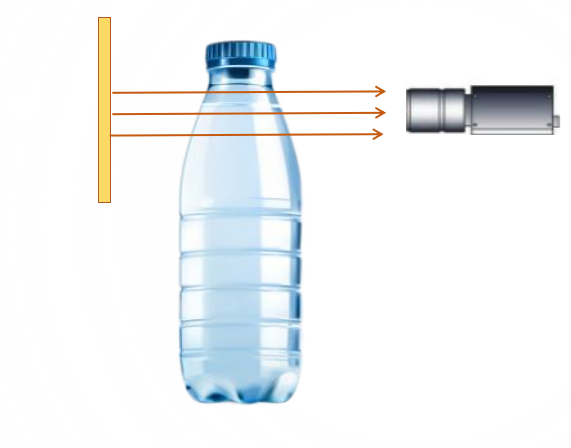

Fill level inspection Module FLI-G utilizes a high quality industrial camera and a maintenance-free LED light source in conjunction with a camera to detect the high and low fill level after filling.

|

Scope of application:

|

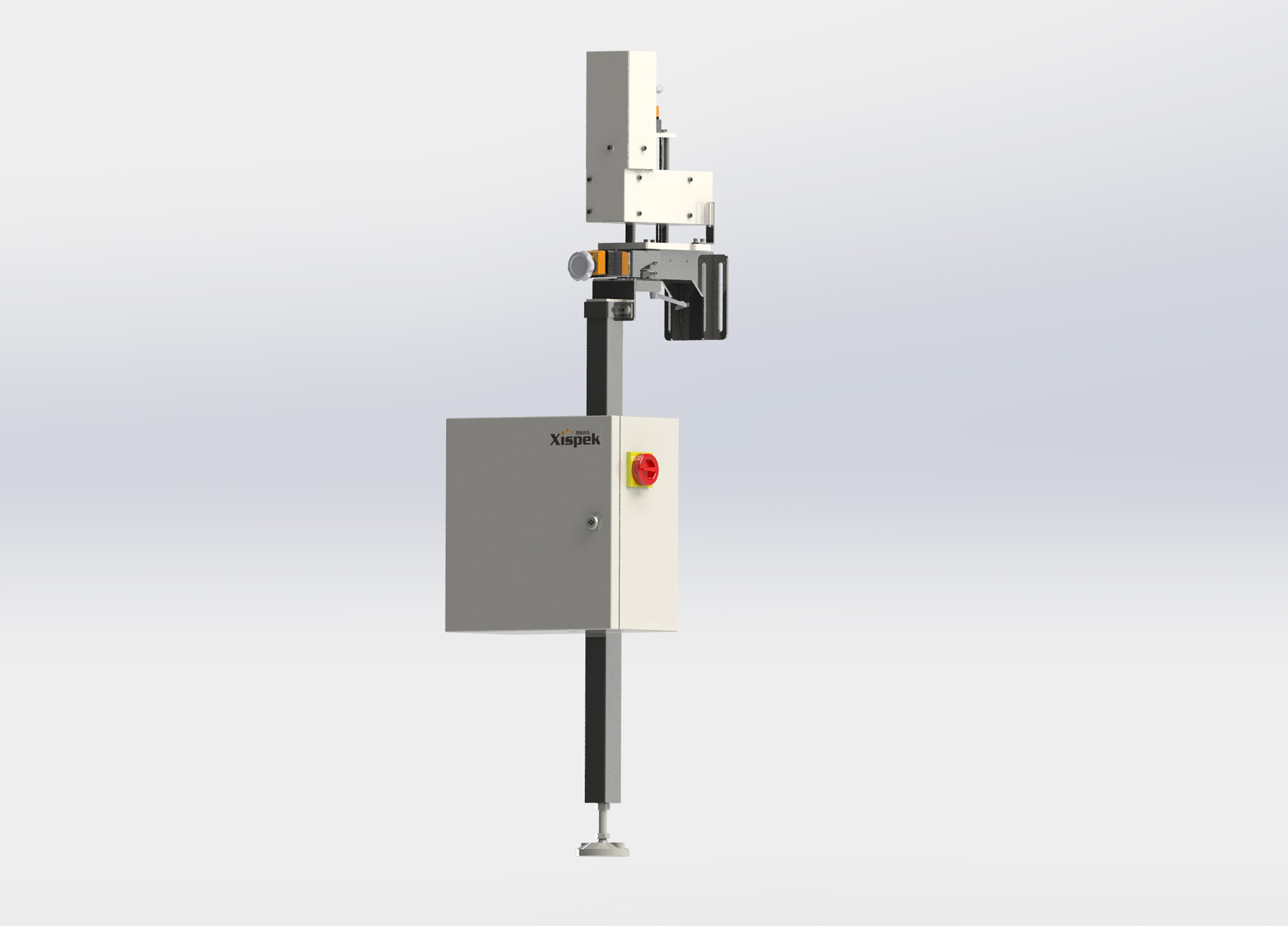

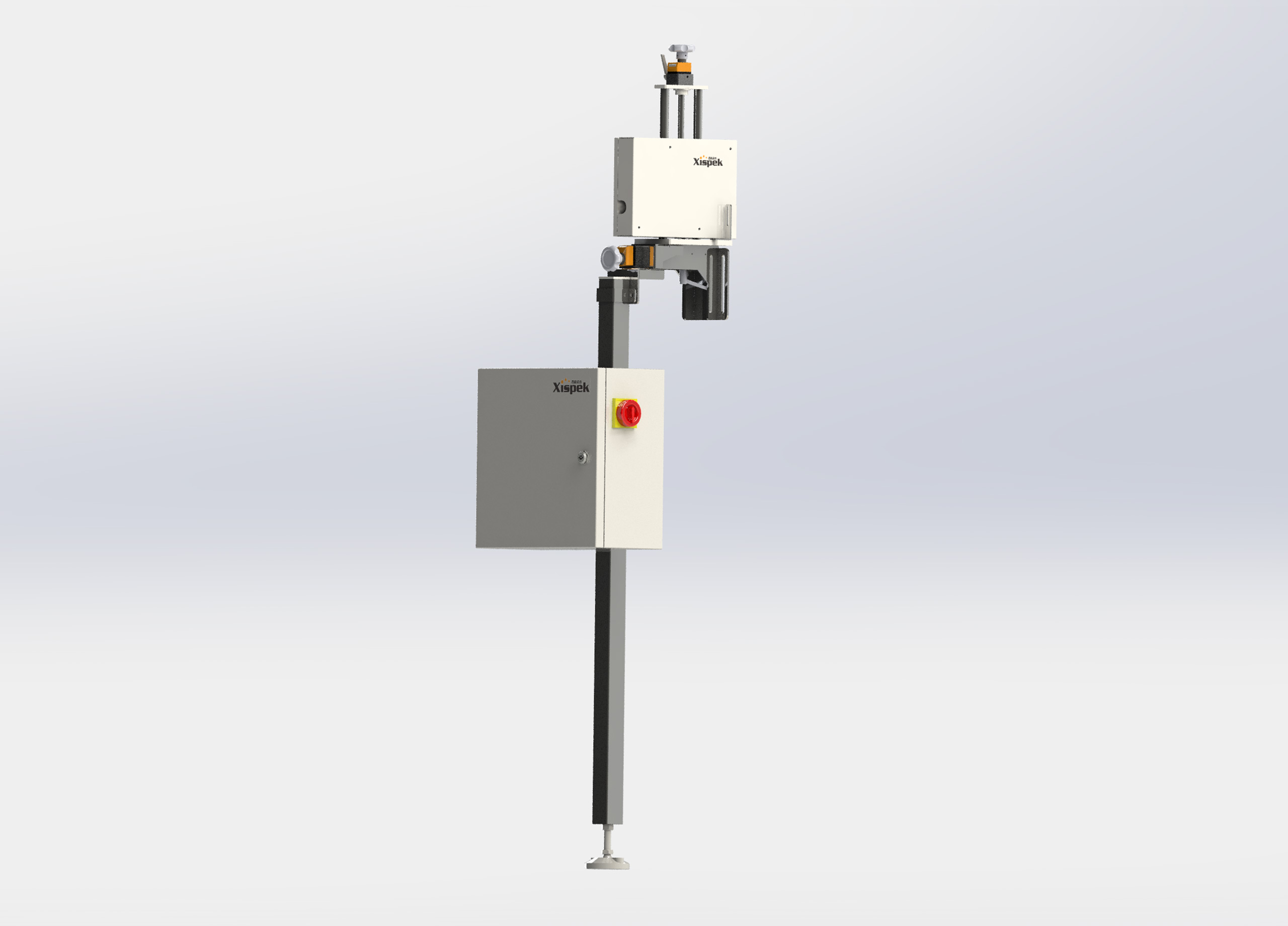

Installation position:

|

High Level

High Level

Low level

Low level

Code inspection (code position in the bottleneck above the level)

Code inspection (code position in the bottleneck above the level)

|

|

|

|

Normal level |

High level |

Low level |

|

|

|

|

Code inspection |

|

|

Fill level inspection Module FLI-G is photographed with a backlight and enables reliable and precise inspection. The modules can be attached directly to the conveyor belt. They not only perform level detection, but also detect the spray code at the neck of the bottle. The inspection modules can be attached directly to the conveyor belt. They not only perform level inspection, but also code inspection at the neck of the bottle. The image processing technology within the advanced XispVision® universal inspection software platform compensates for level shaking, bubbles, etc. on the filling line according to the characteristics of the container and the product, thus enabling accurate level inspection.

Fill level inspection Module FLI-G is an important part of the full bottle inspection after filling. Customers can combine other inspection modules (cap inspection module, four-sided tamper ring inspection module, cover top logo inspection module, code inspection module, etc.) according to their actual needs, as well as the optional functions of the Filling Management System FMS, to form a complete full bottle inspection system.

Utilizes XispVision® universal inspection software platform

Utilizes XispVision® universal inspection software platform

High inspection efficiency and inspection accuracy

High inspection efficiency and inspection accuracy

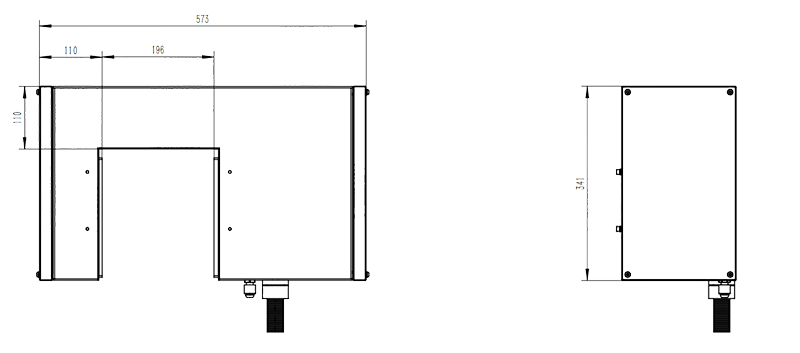

Compact design for easy integration

Compact design for easy integration

Inspection module with IP65 protection level

Inspection module with IP65 protection level

Can be flexibly combined with other modules according to customer needs to form a multi-functional inspection device that meets customer requirements

Can be flexibly combined with other modules according to customer needs to form a multi-functional inspection device that meets customer requirements