ACI (Allied Contamination Inspection) is an online high-speed cap inspection module that can be installed on PET, glass bottles and other canning lines. It is mainly used for the bottle inspection of tamper ring missing, deformed and broken after canning and capping. The module is capable of complete inspection of bottle caps for 360degree, which ensures the safety and sealing of the product.

Scope of application: PET bottle line PET bottle line Glass bottle line Glass bottle line Other production line Other production line |

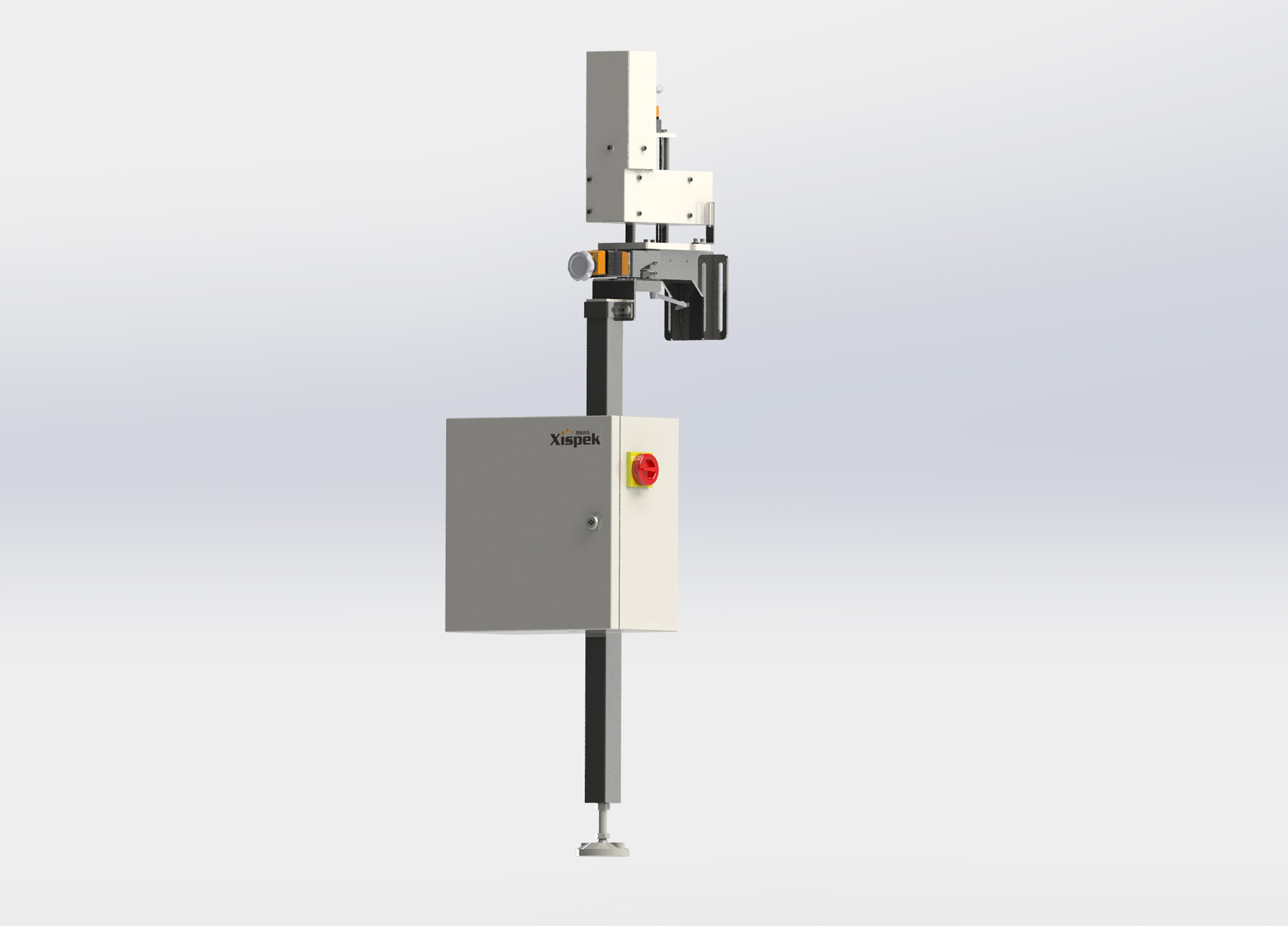

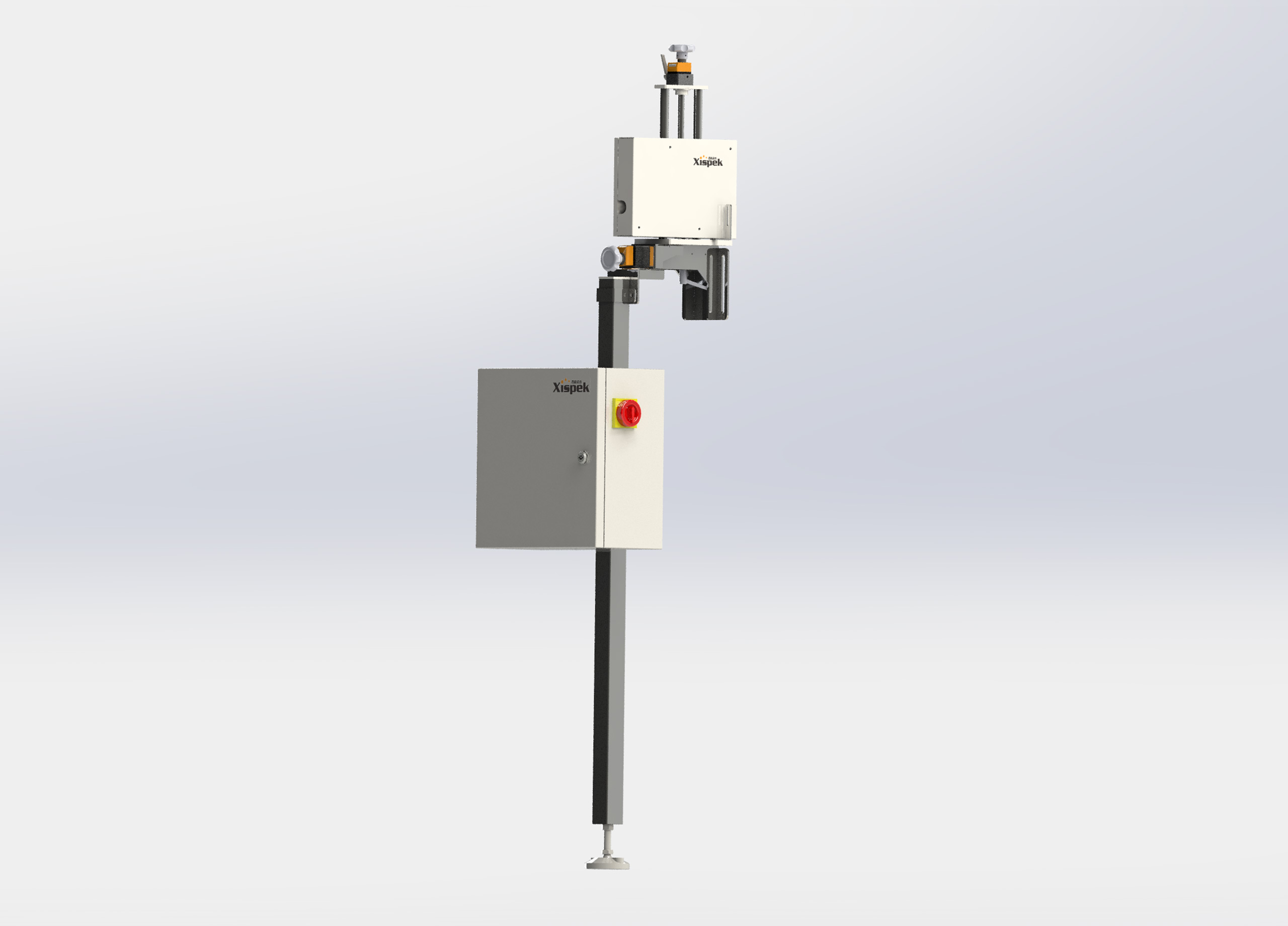

Installation position:

|

Wrong cap

Wrong cap Missing cap

Missing cap Tamper ring missing

Tamper ring missing

Tamper ring broken

Tamper ring broken

|

|

|

|

Wrong cap |

Missing cap |

Tamper ring missing |

|

|

|

|

Tamper ring broken |

|

|

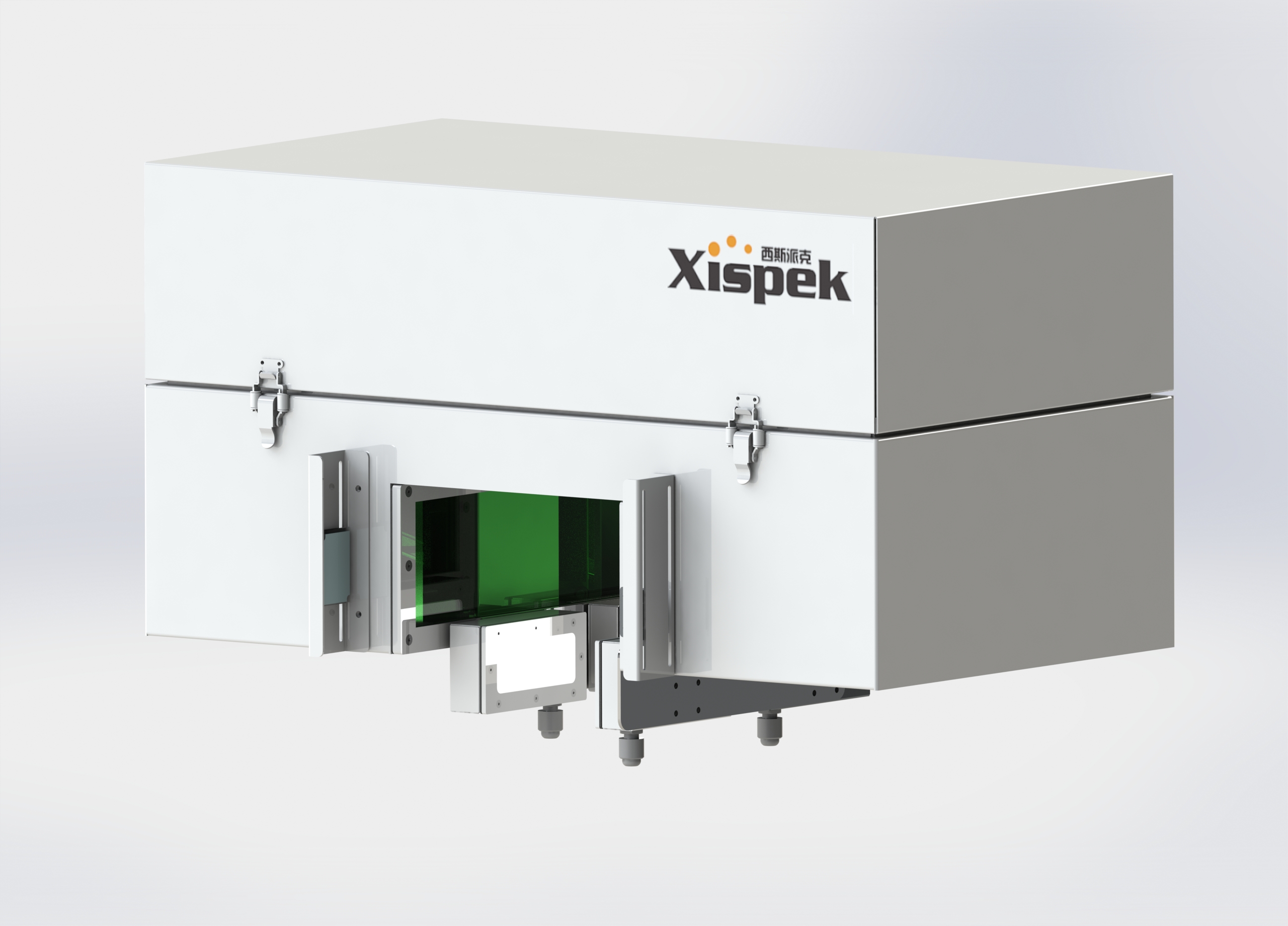

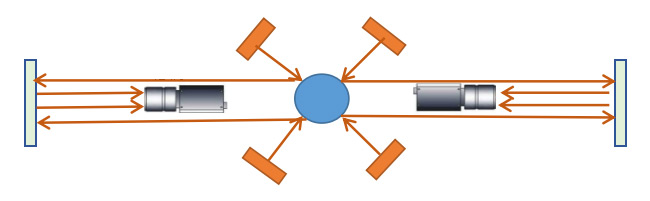

360 degree tamper ring inspection module ACI has an ingenious optical path design that divides the cap into 4 sides (90 degrees each) in an average of 360 degrees for photographing. We use efficient image processing algorithms to accurately detect defects at any angle around the cap, ensuring that every defective cap is accurately inspected.

360 degree tamper ring inspection module ACI is an important part of the full bottle inspection after filling. Customers can combine other inspection modules (cap inspection module, fill level inspection module, cover top logo inspection module, code inspection module, etc.) according to actual needs. At the same time, the optional Filling Management System FMS function is available to form a complete full bottle inspection system.

Adpots XispVision® universal inspection software platform

Adpots XispVision® universal inspection software platform

High inspection efficiency and inspection accuracy

High inspection efficiency and inspection accuracy

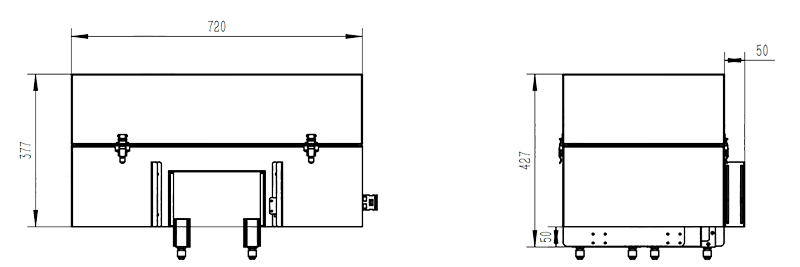

Compact design for easy integration

Compact design for easy integration

Inspection module with IP65 protection level

Inspection module with IP65 protection level

Can be flexibly combined with other functional modules according to customer needs to form a multi-functional inspection device that meets customer requirements

Can be flexibly combined with other functional modules according to customer needs to form a multi-functional inspection device that meets customer requirements