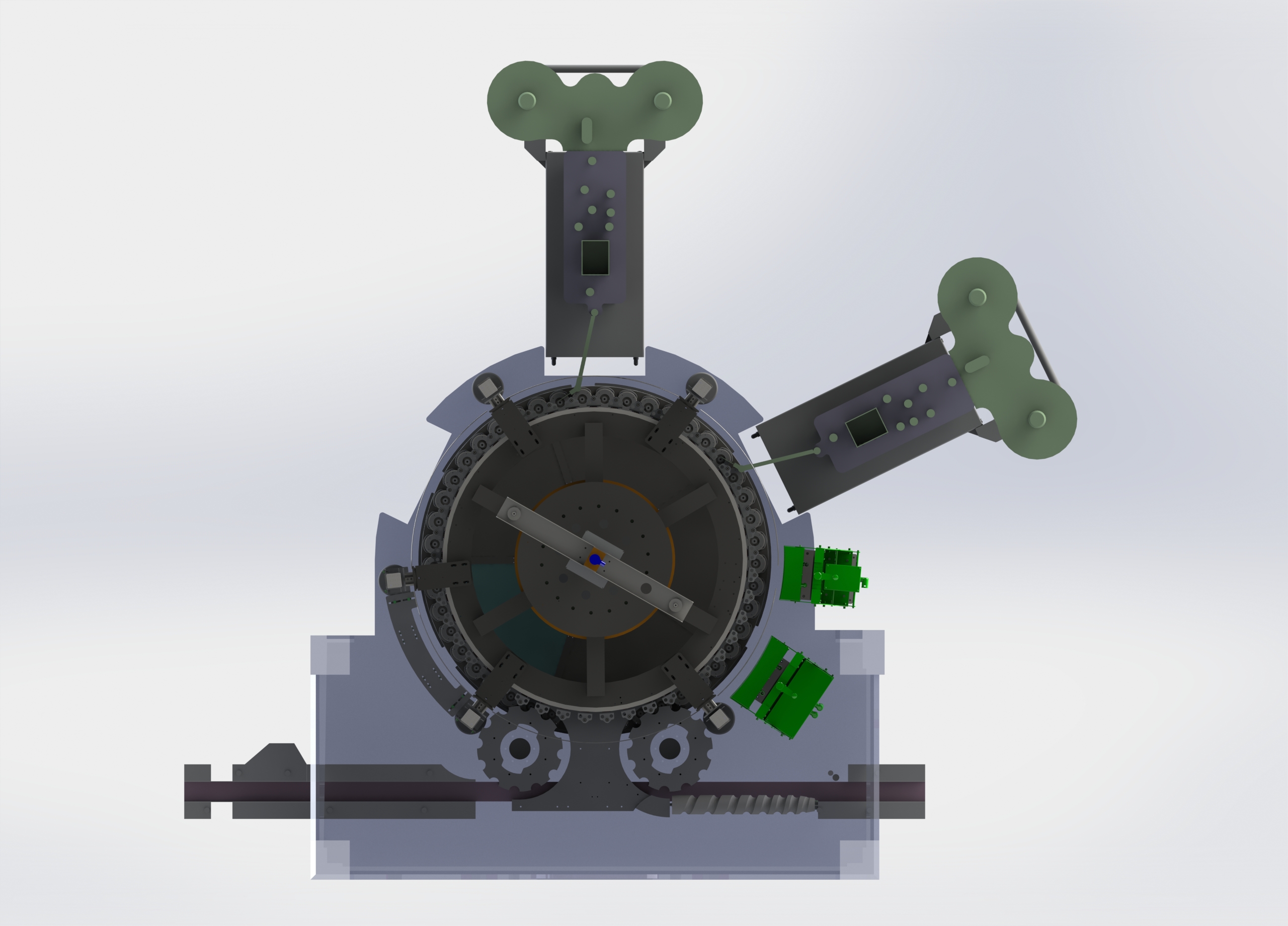

XispVAS is installed inside the labeling machine, and through the principle of machine vision using two-stage positioning can realize the container surface marking, engraving, text, trademarks and other inspection features for positioning. Finally, by controlling the rotation of the servo motor, it realizes high-speed positioning and labeling for the labeling machine.The XispVAS can achieve a maximum of 72,000 bottles per hour of high-speed labeling positioning.

|

Scope of application:

|

Installation Position:

|

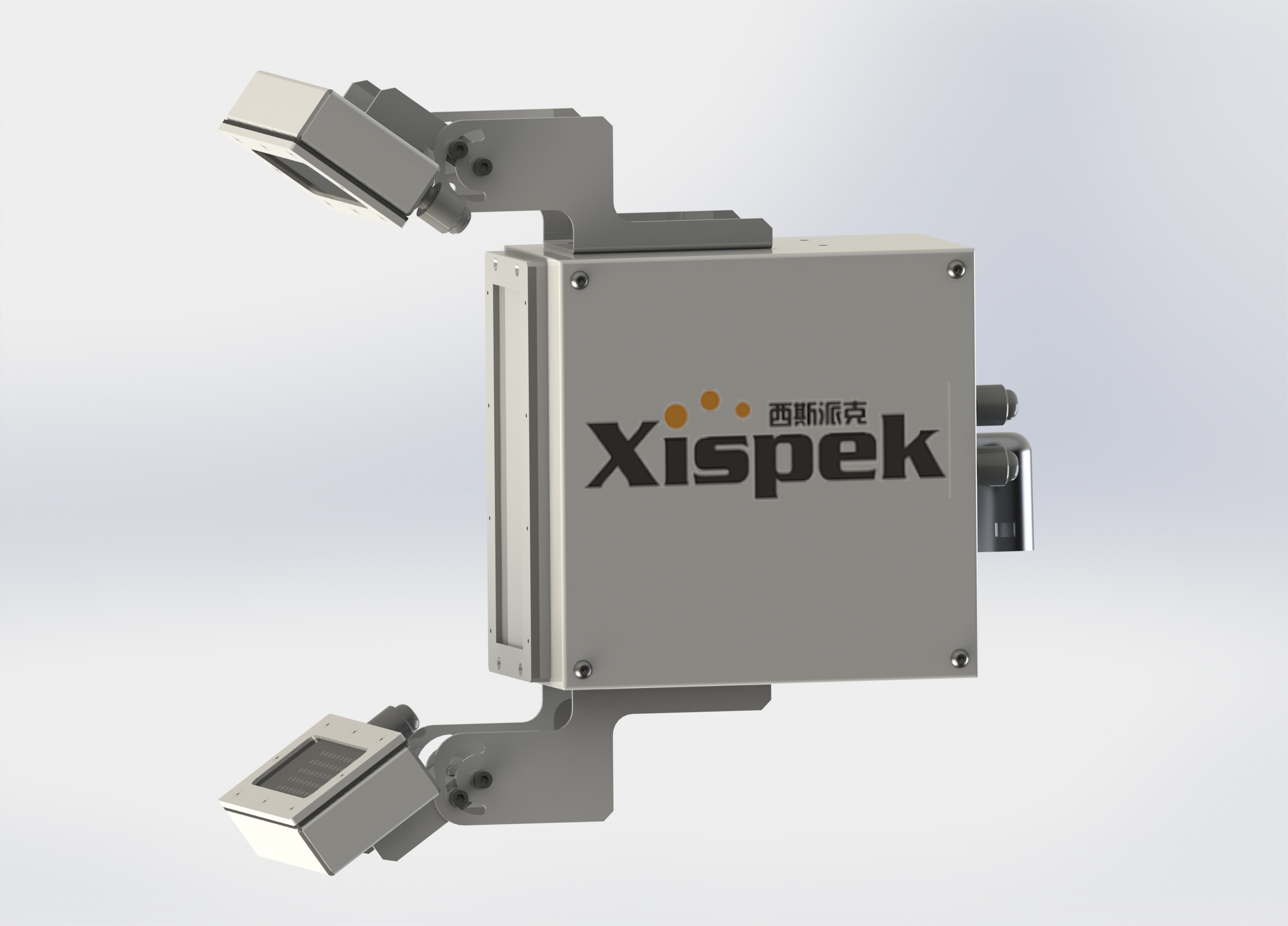

Many customers have customized container design and labeling requirements, such as printed designs or recessed windows on the surface of containers for high-end products in the beer and beverage industry. Labels need to be applied in designated locations for a better visual experience. In addition, containers in the condiment and chemical industries have similar labeling needs. xispVAS positioning system uses vision technology to control the rotation of the servo motors inside the labeling machine to accurately locate the container and ensure a uniform appearance of the product label.The Xispek XispVAS positioning system utilizes two levels of positioning, a rough system and precise alignment system. The rough alignment module utilizes three high-speed industrial cameras. The container rotates during rough alignment, and the rough alignment module photographs the surface of the container several times during the container's rotation to construct a full range of information data about the container. Through the intelligent image processing algorithm to determine the actual position of the container, and finally control the servo motor inside the labeling machine to rotate to complete the first level of positioning function. The precise alignment system again takes pictures of the container surface and makes an amendment to the position of the container to ensure the millimeter-level precision of the positioning.

The Xispek XispVAS positioning system is suitable for a wide range of containers of different materials and sizes, such as glass beer bottles, PET bottles for purified water, as well as large bottles of oil and other types of containers. Xispek offers customized solutions for different containers and features. Please contact us if you have a need, either as a labeling machine manufacturer or as an end-user.

Precision positioning:

The Precision positioning module uses three high-speed industrial cameras. The container rotates in the process of Precision positioning, and the pre-positioning module shoots the surface of the container several times during the process of container rotation to construct all-round information data of the container. Through the intelligent image processing algorithm to determine the actual position of the container, and finally control the servo motor rotation in the labeling machine to complete the first level of positioning function.

Reservation:

The Reservation System again takes a picture of the container surface and makes a correction to the position of the container to ensure millimeter-level accuracy in positioning.

Powerlink

Powerlink

TCP/IP

TCP/IP

Modbus/TCP

Modbus/TCP

Ethernet/IP

Ethernet/IP

ProfiNet

ProfiNet

CAN

CAN

Adopts XispVision® universal inspection software platform

Adopts XispVision® universal inspection software platform

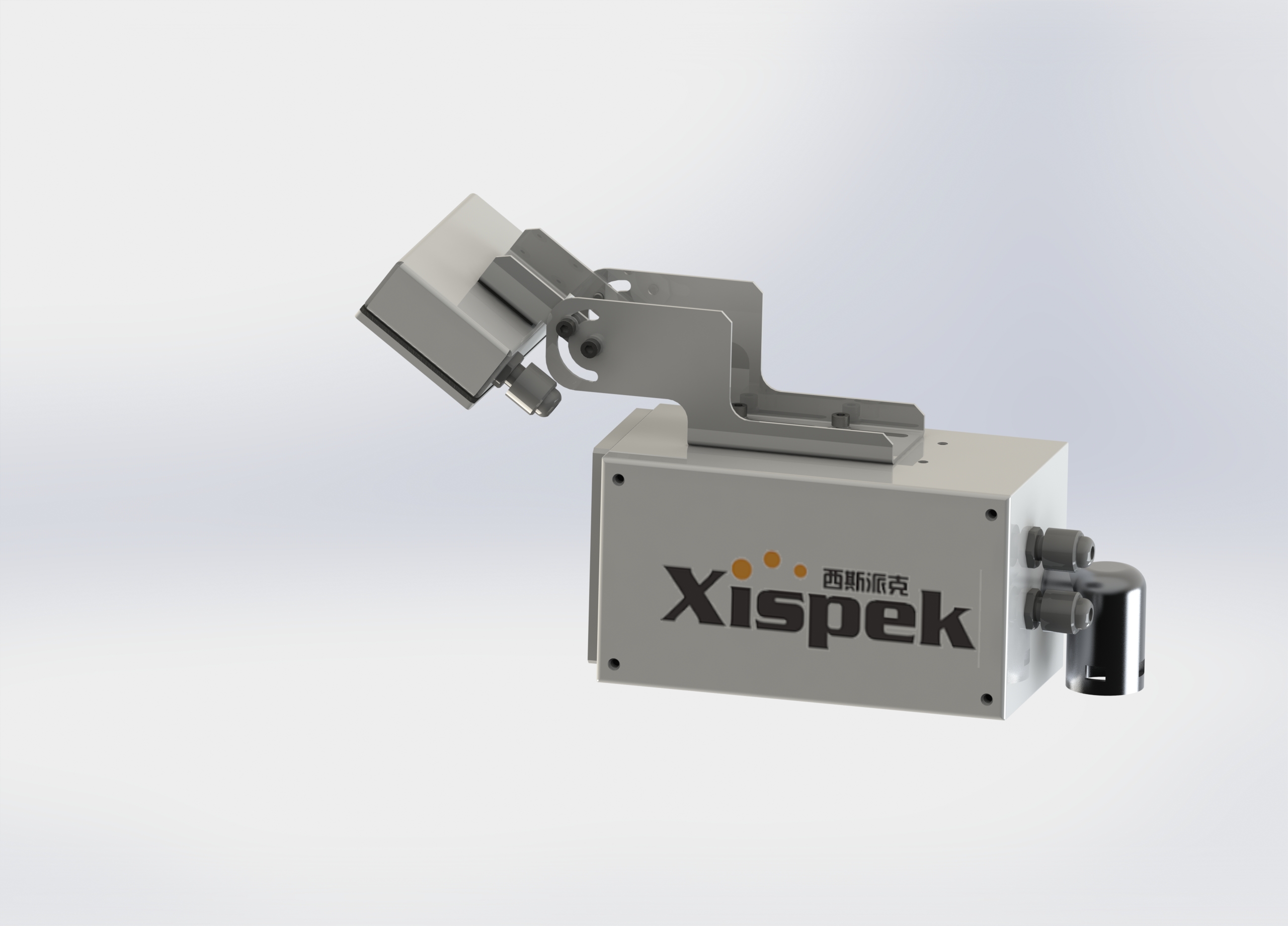

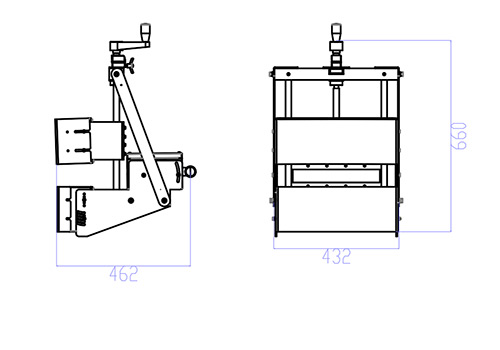

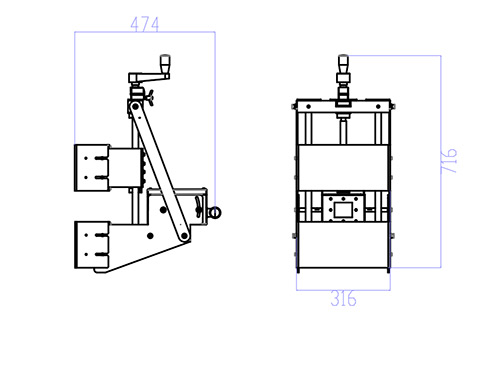

Compact and easy to integrate into the labeling machine

Compact and easy to integrate into the labeling machine

Non-contact positioning, no abrasion

Non-contact positioning, no abrasion

Simple changeover, no need to replace product parts

Simple changeover, no need to replace product parts

Hygienic design for various environment

Hygienic design for various environment