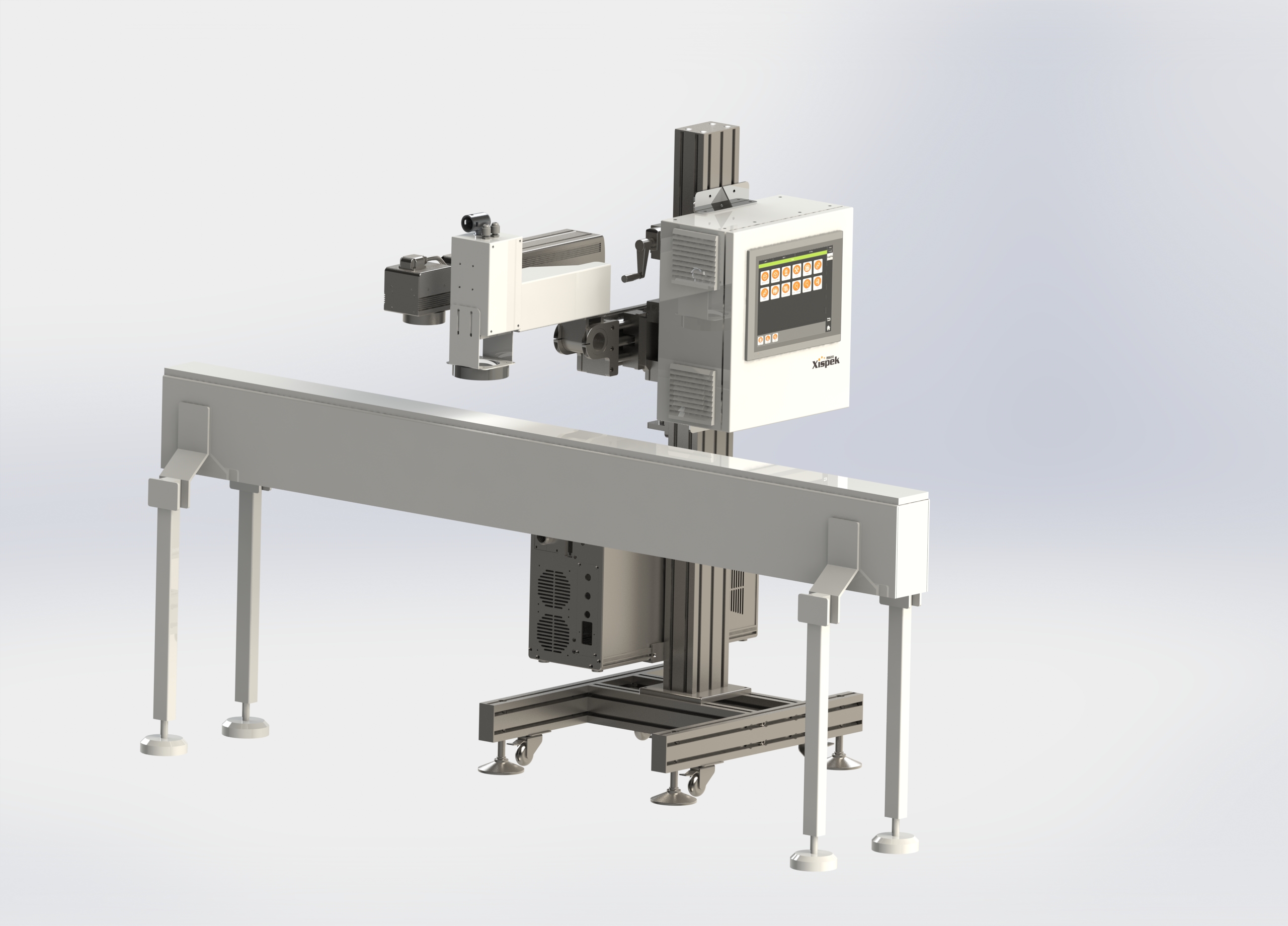

VisPrinter is an integrated coding and Inspection machine. It is usually used to print codes on products (e.g. date, batch number, barcode, etc.) and to inspect the codes at the same time (e.g. to verify the accuracy and clarity of the codes). This equipment increases the efficiency and accuracy of the production line and reduces errors.

Code missing

Code missing

Wrong code printing

Wrong code printing

Barcode, 2D code reading and verification

Barcode, 2D code reading and verification

The VisPrinter is an integrated coding and code inspection machine for coding and inspection of goods at the same time. VisPrinter enables uniform adjustment of dates and changeovers, reducing changeover time and at the same time reducing equipment costs as well as on-site service time.

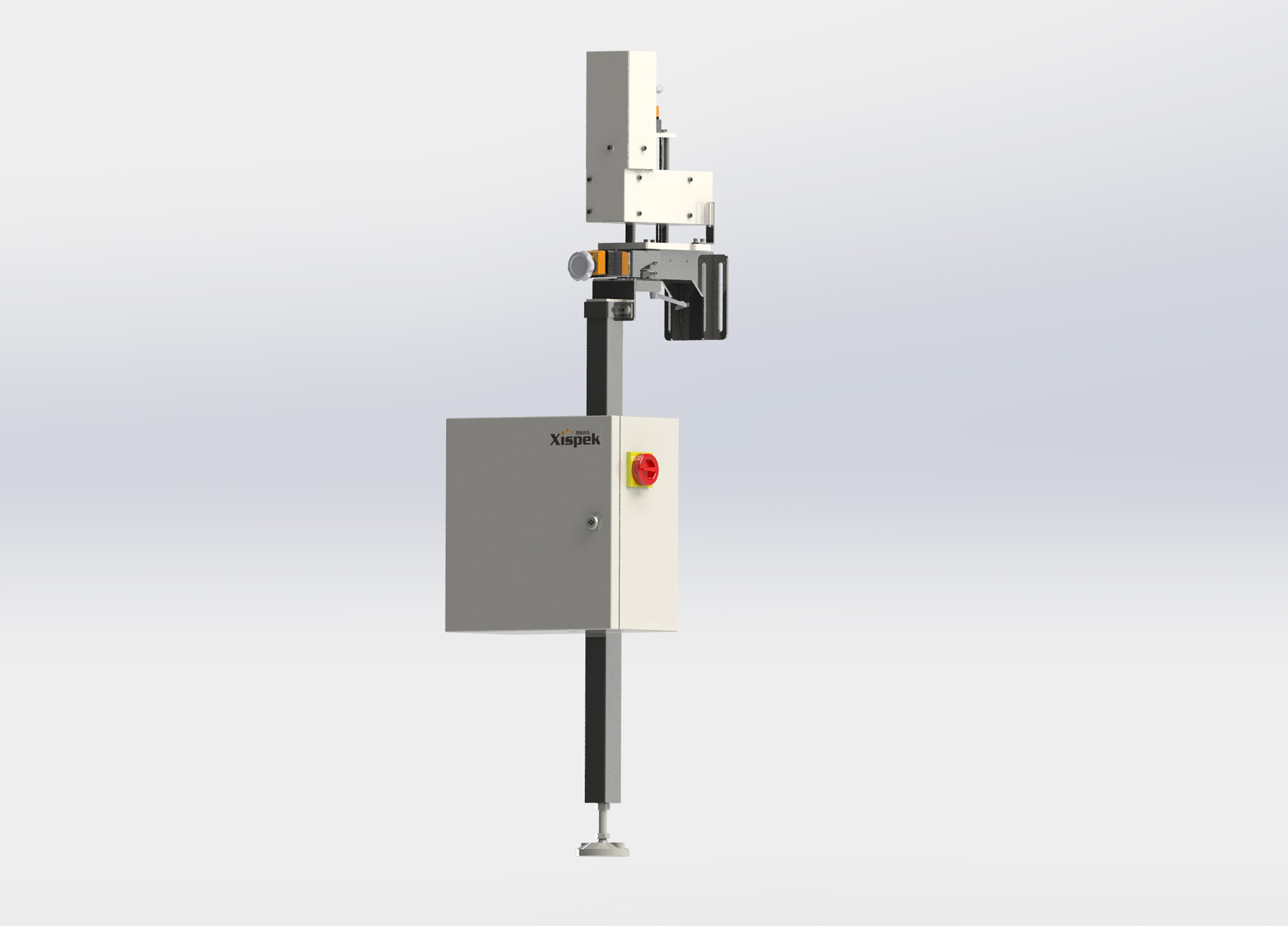

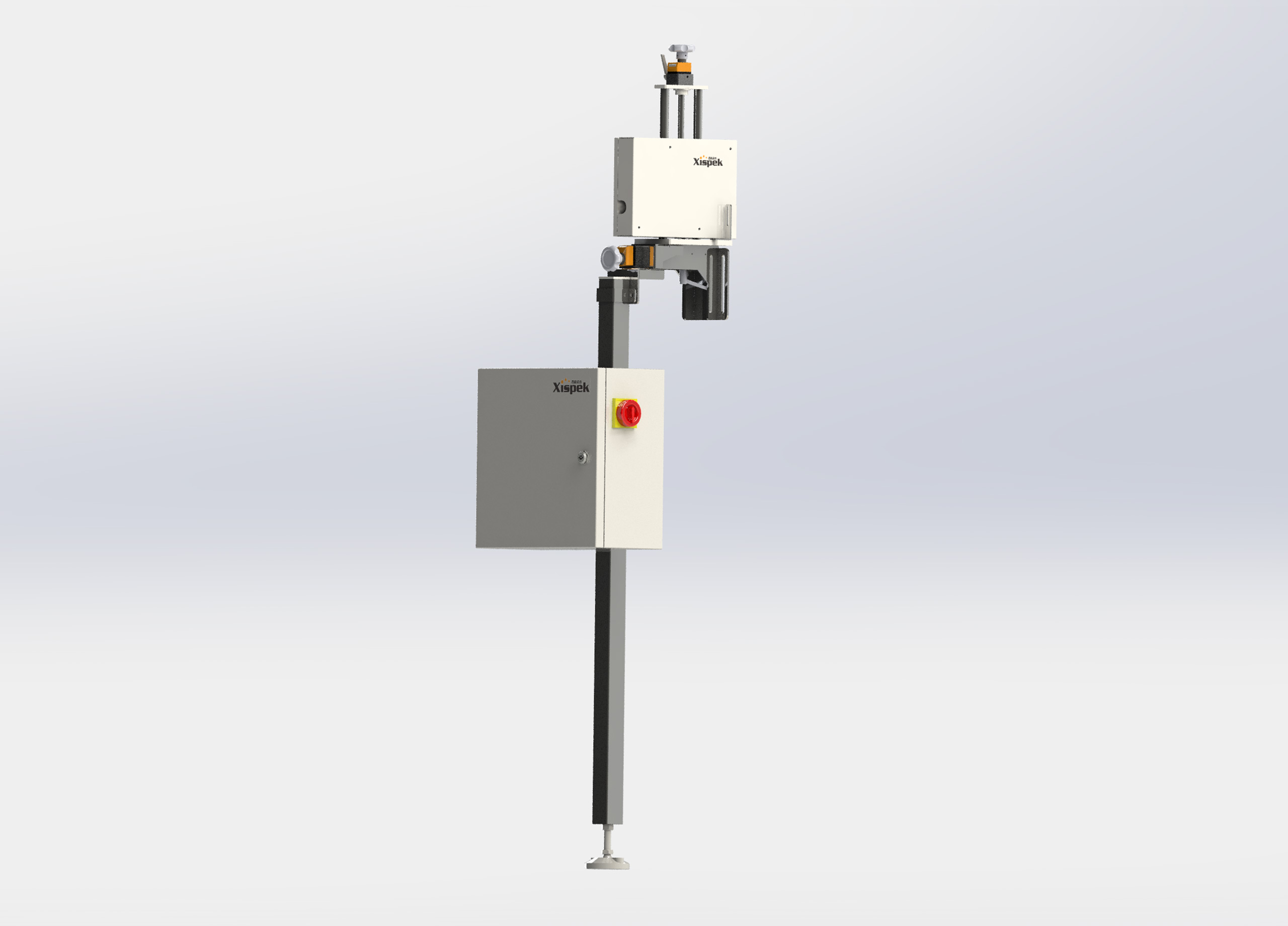

3D view of the localized adjustment sector for code checking

3D view of the localized adjustment sector for code checking

Unified mechanical adjustment, no need for multiple adjustments

Unified mechanical adjustment, no need for multiple adjustments

Integrated design saves installation space

Integrated design saves installation space

Code date one-time adjustment

Code date one-time adjustment

TCP/IP communication

TCP/IP communication

Can choose coding, laser or fiber laser printers according to requirements

Can choose coding, laser or fiber laser printers according to requirements

XispSmart optional for different type of application

XispSmart optional for different type of application

Lower costs for slow production lines

Lower costs for slow production lines

Adopts XispVision® inspection software platform

Adopts XispVision® inspection software platform

Compact design for easy integration

Compact design for easy integration

IP65 protection level, adapt to various environments

IP65 protection level, adapt to various environments

Coding machines take into account the need for code inspection

Coding machines take into account the need for code inspection

Low cost, easy installation

Low cost, easy installation

Coding Module

Coding Module

● Inkjet Coding

● Carbon dioxide laser coding

● Fiber laser coding

● UV laser coding