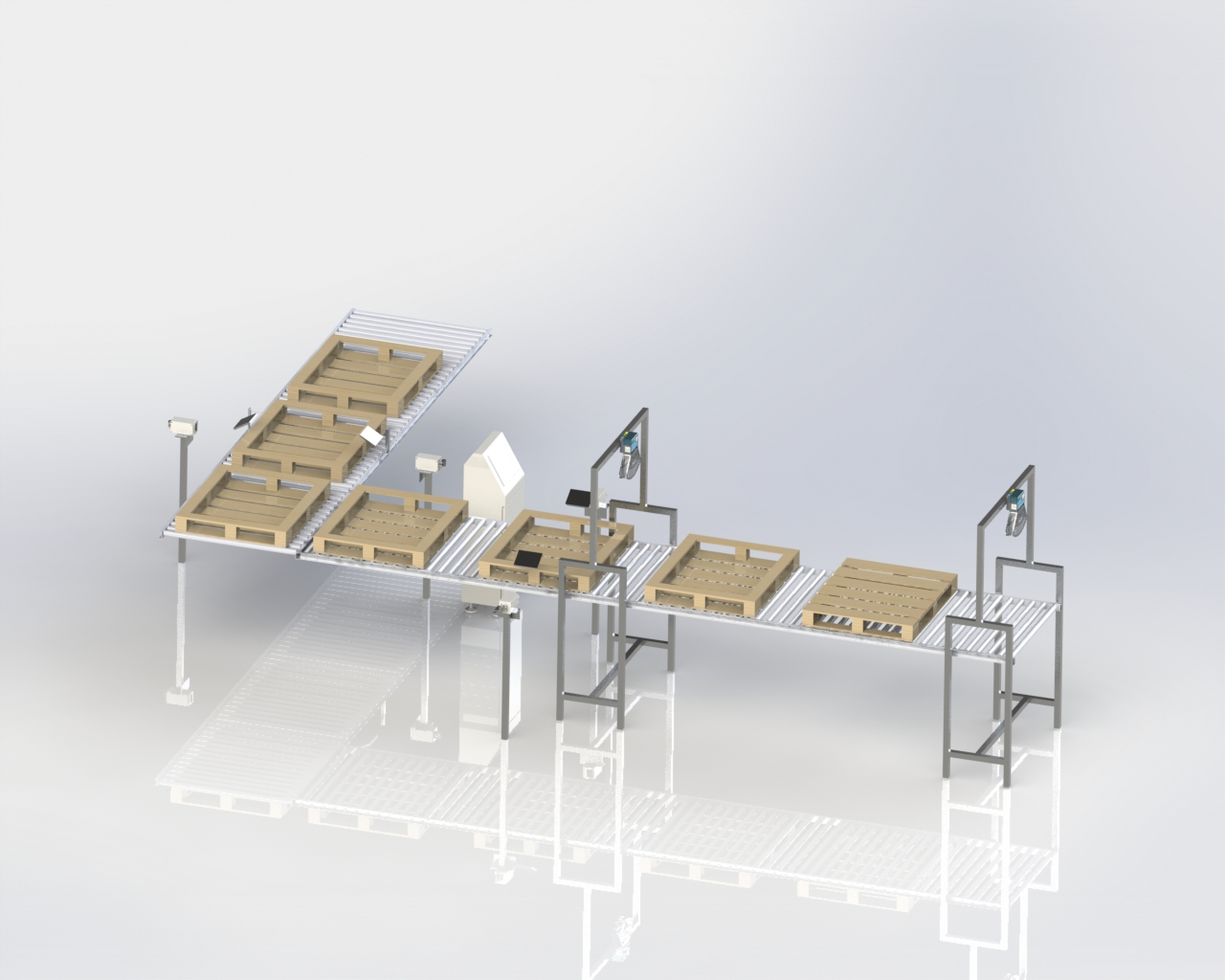

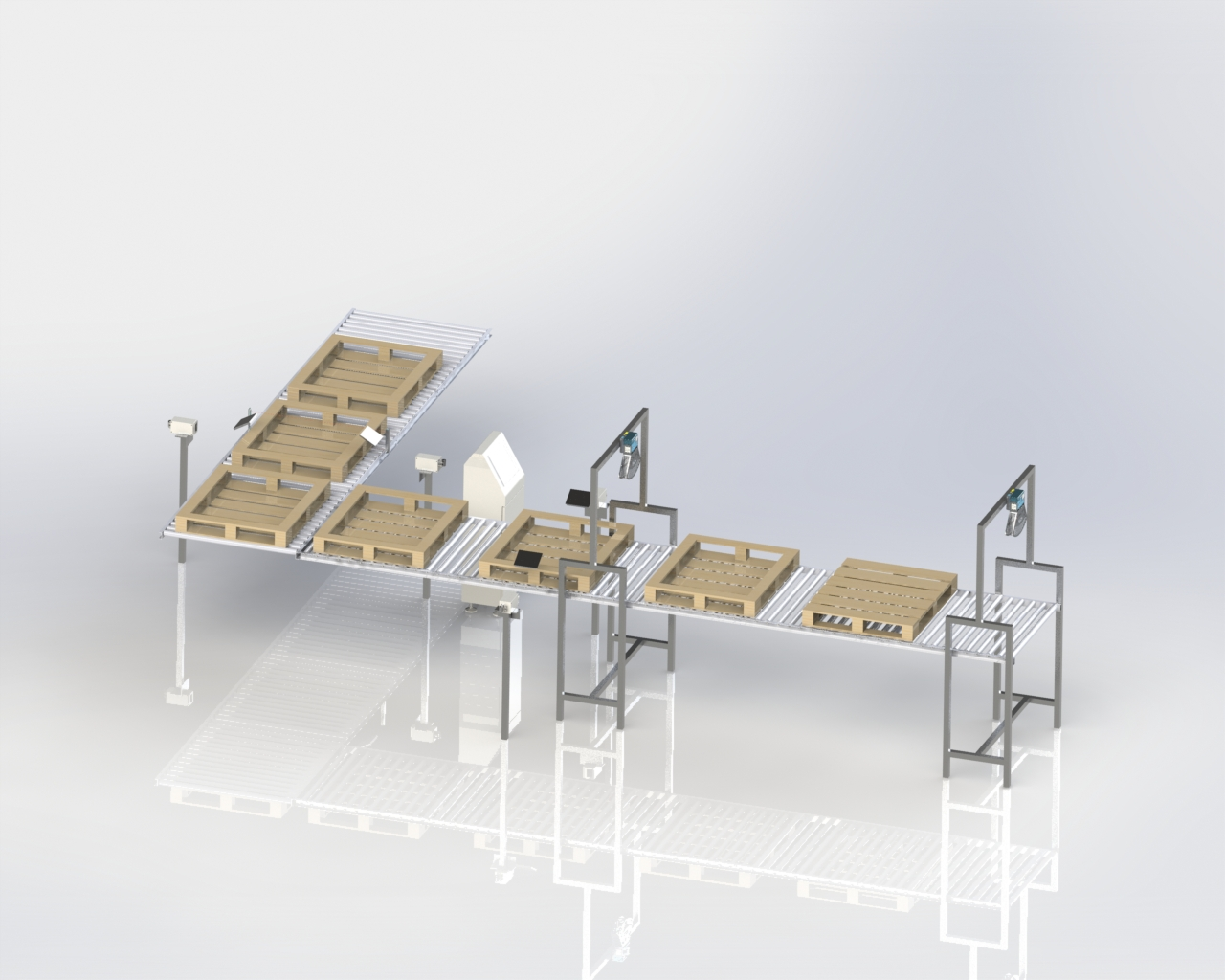

The Recycled Wooden Pallet Inspection System is a system for evaluating and inspecting wooden pallets for its suitability for re-use or recycling. It uses sensors and vision recognition technology to inspect parameters such as the quality and size of the wooden pallet and also recognize the markings on the wooden pallet. Using high-speed industrial cameras and the independently owned XispVision® universal inspection software platform to accurately and efficiently recognize codes and reject defective products.

Wooden pallet broken

Wooden pallet broken

Wooden pallet nails sticking out

Wooden pallet nails sticking out

Wooden pallet missing beams, beams broken

Wooden pallet missing beams, beams broken

Pallet feet broken

Pallet feet broken

The Recycled Wooden Pallet Inspection System is an inspection system for wooden pallets on production lines. Using high-speed industrial cameras and the independent and autonomous XispVision® universal inspection software platform, it can accurately and efficiently identify broken wooden pallets, raised nails, missing beams, broken beams, etc. The system rejects defective products, reduces the number of defective products, and improves production efficiency and product quality. Depending on the actual line speed the customer can choose between different control centers and inspection modules, which are used to inspect the wooden pallets.

Integrated design, higher reliability, smaller installation space

Integrated design, higher reliability, smaller installation space

Synchronized system adjustment for better application flexibility

Synchronized system adjustment for better application flexibility

Integrated control, more stable and accurate inspection and rejection

Integrated control, more stable and accurate inspection and rejection

Flexible configuration, according to different needs and requirements, has an ultra-wide range of applications

Flexible configuration, according to different needs and requirements, has an ultra-wide range of applications

Control center and inspection system are optional to cope with different scenarios

Control center and inspection system are optional to cope with different scenarios

Adopts XispVision® Inspection Software Platform

Adopts XispVision® Inspection Software Platform

High inspection efficiency and accuracy

High inspection efficiency and accuracy

Compact design for easy integration

Compact design for easy integration

IP65 protection level, adapt to various environments

IP65 protection level, adapt to various environments

Compatible with all types of recycled wood pallet inspection

Compatible with all types of recycled wood pallet inspection

Recycled Wood Pallet Inspection System

Recycled Wood Pallet Inspection System

Control Center

Control Center

● Integrated XispC1000

● Integrated XispC2000