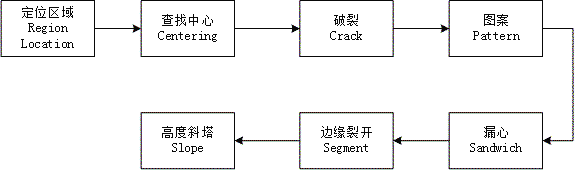

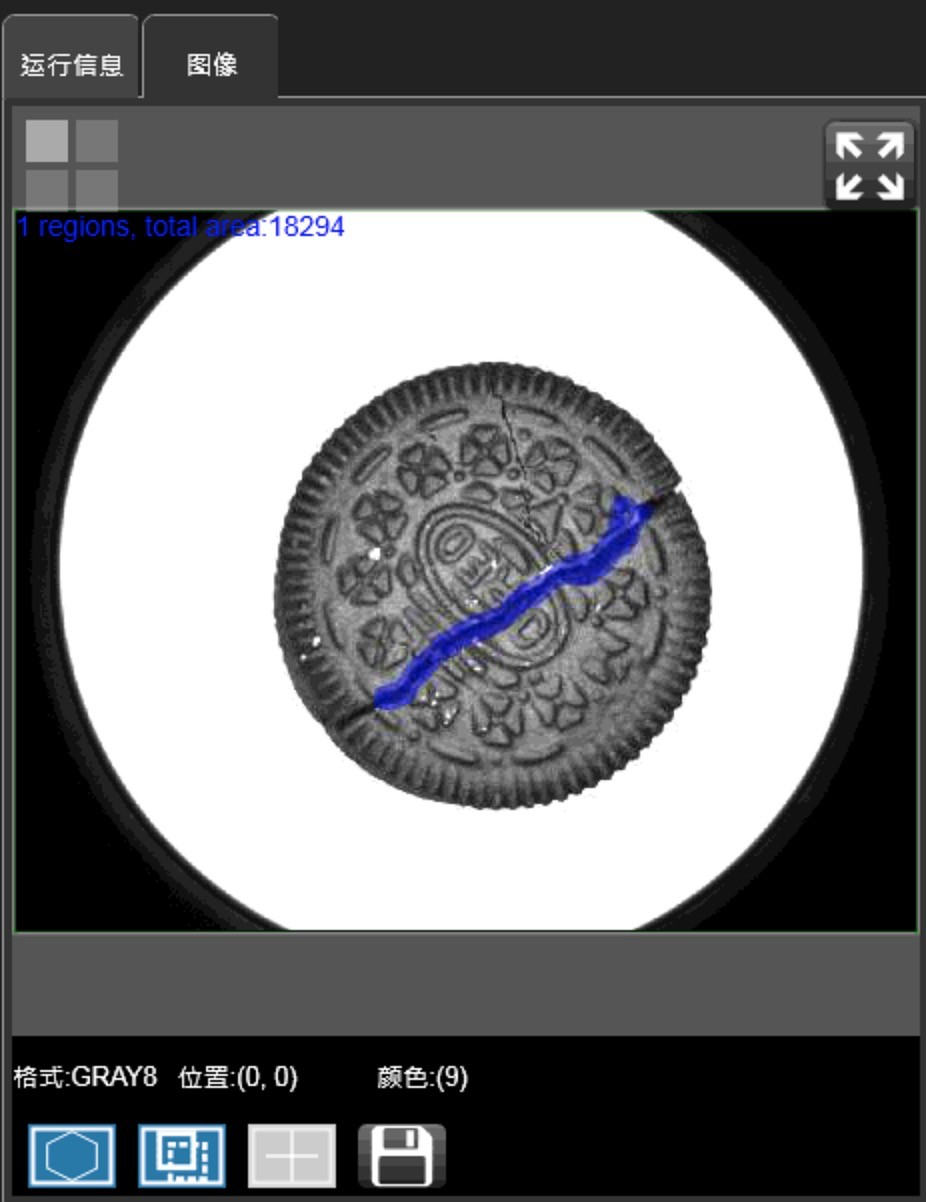

The CaCooka 6600 inspection system is a system for sandwich cookie quality inspection using advanced visual recognition technology. The system is installed on the cookie production line after the centering machine, and can perform online inspection and rejection of defective cookies in real time for defects such as missing top cover, reversal, overfilling, cracking, missing corner, and dimensions defects. When the system inspects the cookies with quality problems, it will trigger the rejection device to remove the unqualified cookies from the production line, ensuring that only qualified cookies go to the next process.

|

Scope of application:

|

Installation position:

|

Top cover missing

Top cover missing

Reversal

Reversal

Overfilling

Overfilling

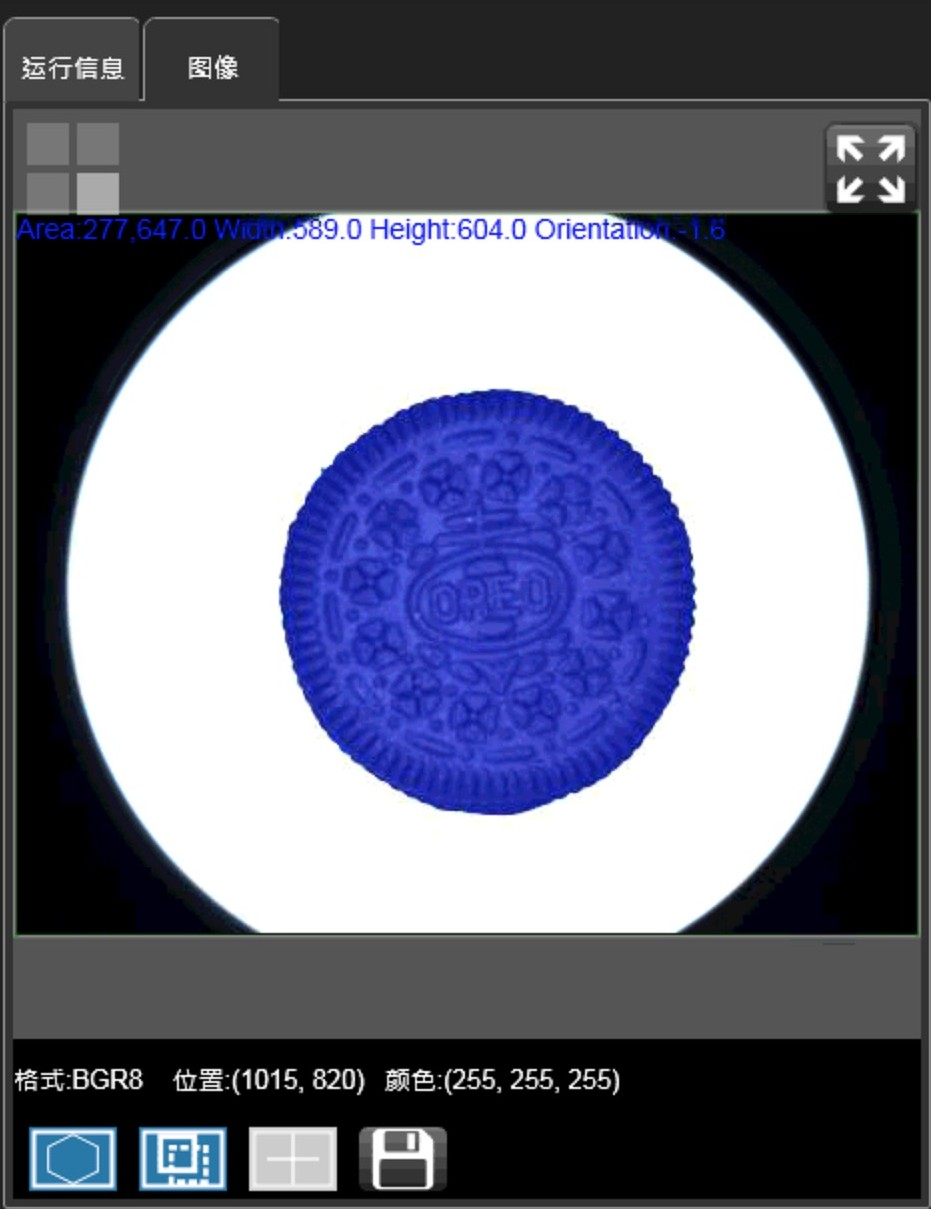

Cracking

Cracking

Missing corner

Missing corner

Size

Size

|

|

|

|

Top cover missing |

Reversal |

Overfilling |

|

|

|

|

Cracking |

Missing corner |

Size |

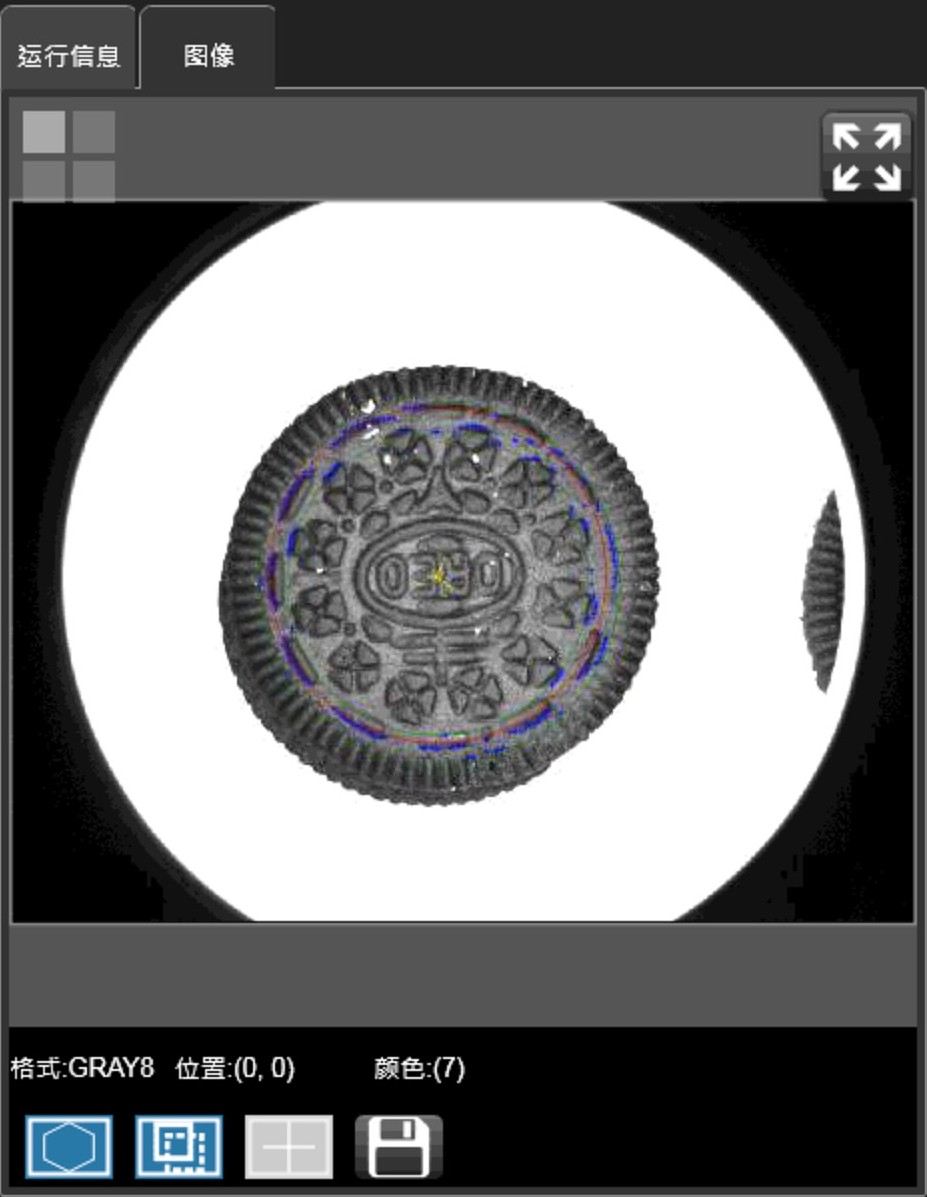

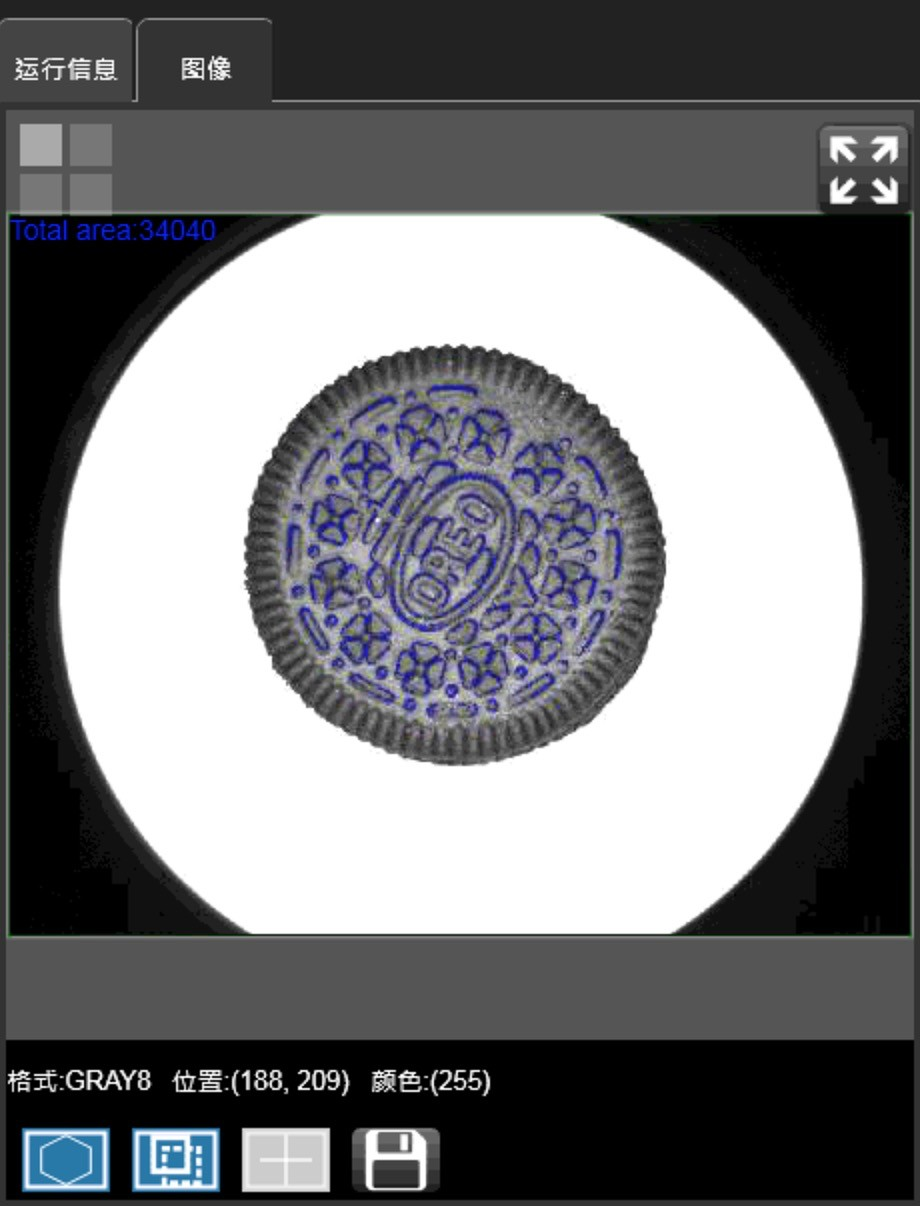

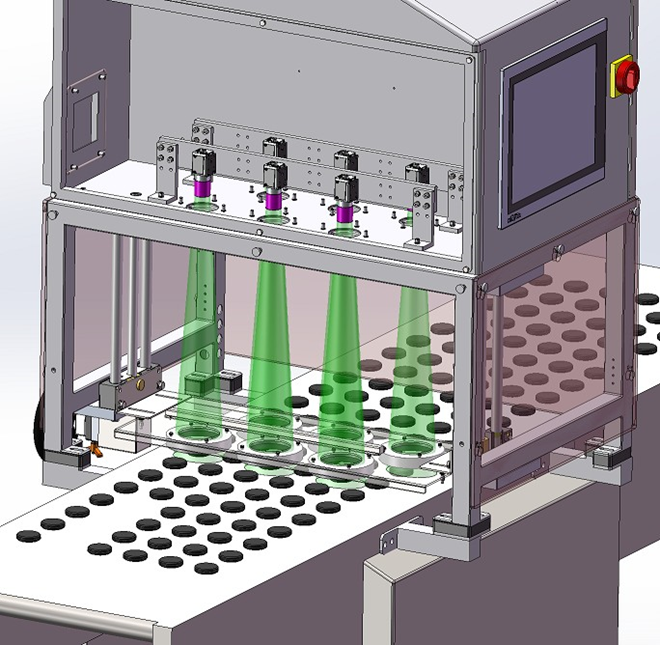

The sandwich cookie inspection machine CaCooka 6600 offers several advantages. Firstly, it uses a combination of advanced laser sensors and visual recognition technology to quickly and accurately inspect sandwich cookies for all defects, including missing cover, reversal, overfilling, cracking, missing corner and dimensions defects. All defective products are rejected online to a defective product collection conveyor through a pusher to ensure product quality meets the standard. CaCooka 6600 has a humanized integrated design. It can be applied to different filling colors, base cake colors, and specifications of sandwich cookies, realizing the function of one-button changeover, which reduces the time for customers to changeover and saves the labor and time cost.

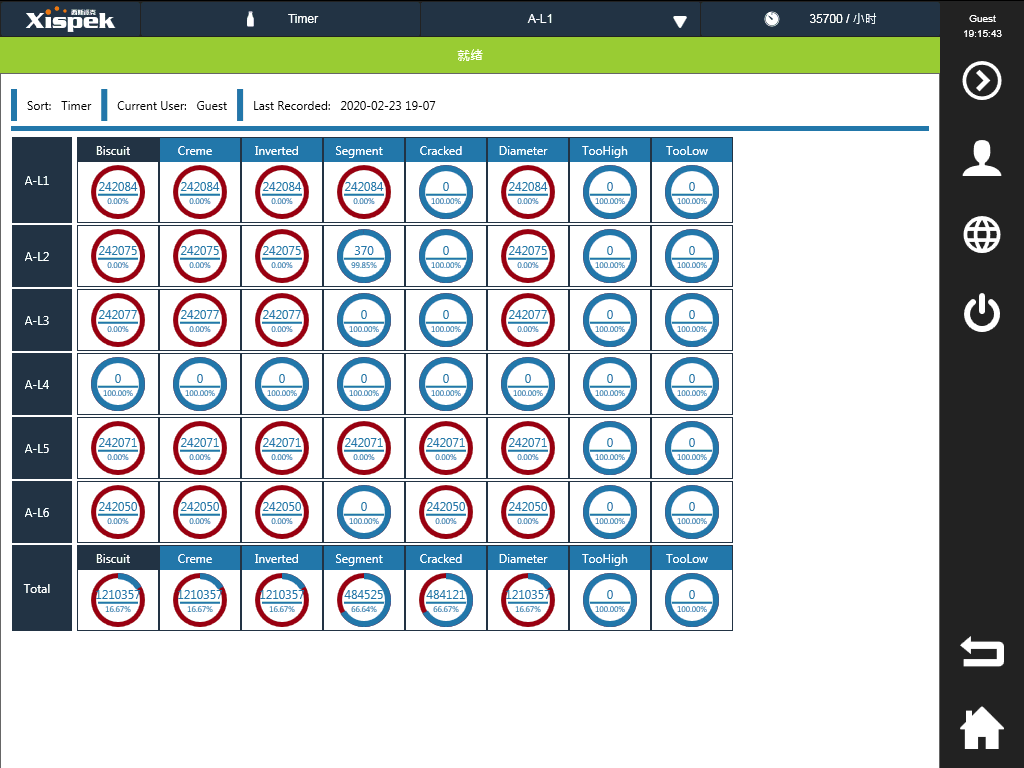

CaCooka 6600 is also capable of real-time statistics and recording of daily inspection data, which can help manufacturers to carry out quality management and process improvement, and provides a variety of communication protocol interfaces to facilitate customer data collection. In conclusion, CaCooka 6600 as sandwich cookie inspection equipment plays an important role in improving production efficiency and product quality. Its advantages of high precision, speed and accuracy, adaptability and data recording and analysis enable manufacturers to better control product quality and provide quality sandwich cookie products that meet consumer expectations.

The CaCooka 6600 is capable of inspecting up to 6 lanes of cookies at the same time, with a maximum speed of 600 slices/minute per lane. Of course, we can customize the solution according to the number of product lanes in the customer's production line.

Long working distance to ensure clean equipment standards

Long working distance to ensure clean equipment standards

Sensors can be cleaned directly during the production

Sensors can be cleaned directly during the production

Stable triggering and measurement

Stable triggering and measurement

Ultra-high measurement accuracy, repeatability <0.01mm

Ultra-high measurement accuracy, repeatability <0.01mm

Camera sealed inside IP65 inspection module

Camera sealed inside IP65 inspection module

Vision components are kept away from cookies, hygienic grade design

Vision components are kept away from cookies, hygienic grade design

The light source can be adjusted up and down, easy for production and maintenance

The light source can be adjusted up and down, easy for production and maintenance

Individual LED light source for each channel, maintenance-free

Individual LED light source for each channel, maintenance-free

Integrated touch screen operation, convenient and quick

Integrated touch screen operation, convenient and quick

No moving parts, simple and safe

No moving parts, simple and safe

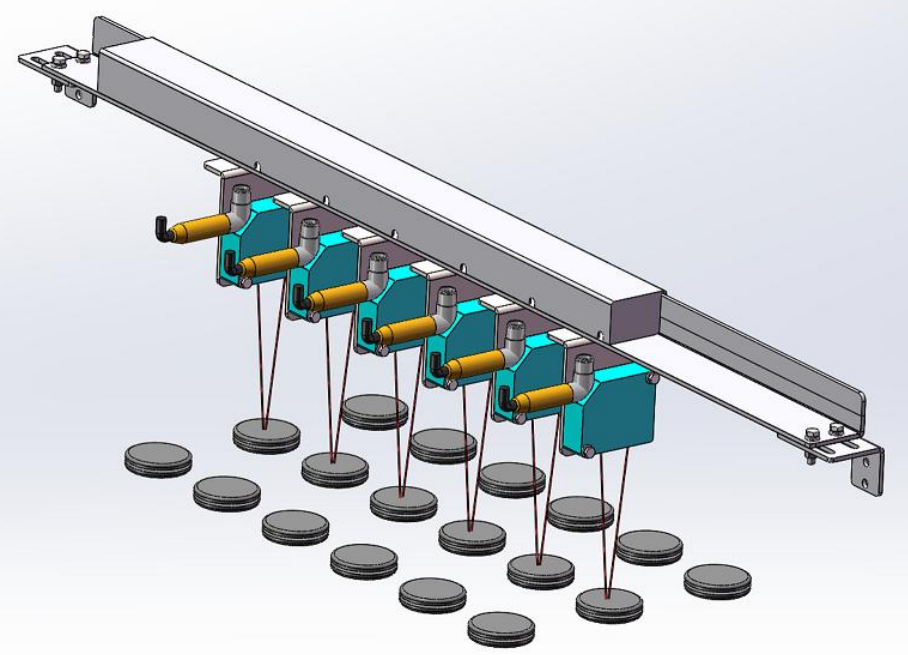

Food grade stainless steel air nozzles

Food grade stainless steel air nozzles

All air nozzles are individually adjustable

All air nozzles are individually adjustable

High speed rejects up to 15 cookies per second

High speed rejects up to 15 cookies per second

Built-in air storage tank for continuous rejections

Built-in air storage tank for continuous rejections

Air pressure alarm function ensures stable rejection

Air pressure alarm function ensures stable rejection

Adopts XispVision® universal inspection software platform

Adopts XispVision® universal inspection software platform

Provides detailed statistics

Provides detailed statistics

Unified communication protocol data interface is convenient for customers to collect data (OPC-UA/Modbus-TCP)

Unified communication protocol data interface is convenient for customers to collect data (OPC-UA/Modbus-TCP)

The whole machine is made of all stainless steel, food-grade hygiene standard design

The whole machine is made of all stainless steel, food-grade hygiene standard design

High inspection efficiency and inspection accuracy

High inspection efficiency and inspection accuracy

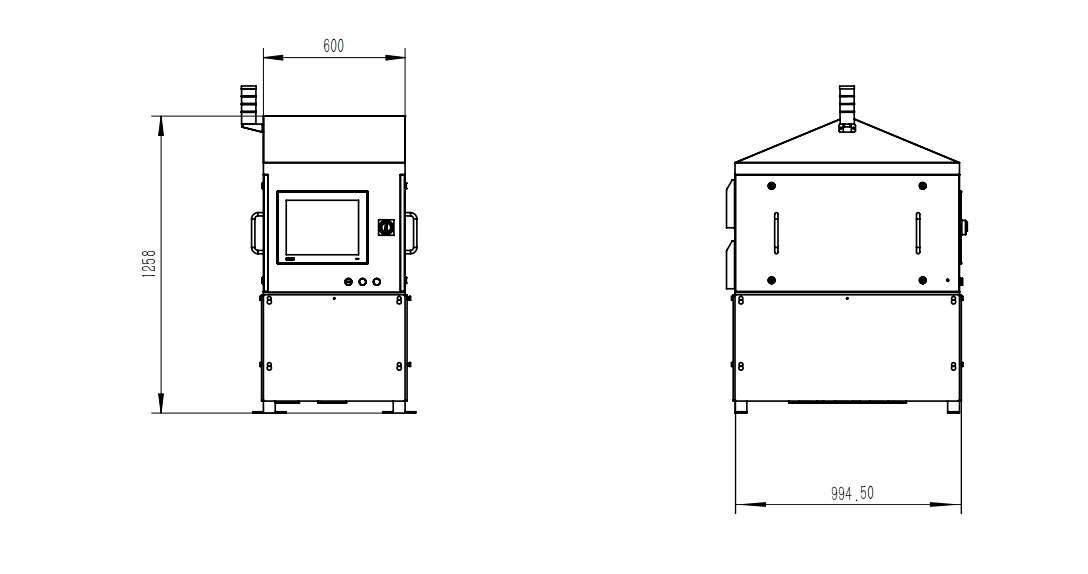

Compact design for easy integration

Compact design for easy integration

IP65 protection level, adapt to various environments

IP65 protection level, adapt to various environments

Compatible with all types of sandwich cookies, one-click changeover

Compatible with all types of sandwich cookies, one-click changeover

Sandwich Cookie Inspection CaCooka 6600

Sandwich Cookie Inspection CaCooka 6600

Control center

Control center

● Integrated Control Center

Pusher

Pusher● Integrated Reject Nozzle

Customized Conveyor

Customized Conveyor